rapid tooling,molding in silicon moud/customized products rapid prototype making silicon moulding

Quick Detail

- Minimum order:1

- Place of Origin:china

Specifications

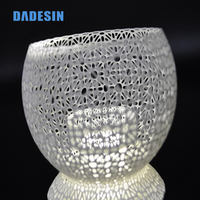

Vacuum casting or silicone molding technology uses the model which produces by CNC machining or 3D printing method, to make the silicone mold in vacuum. And uses PU material to fill out silicone

mold cavity in vacuum, to form the exact same model as the prototype.

In rapid prototyping industry, Vacuum casting or Silicone molding is a very common method. It is mainly used in making plastic product at low volume.Usually, if prototype with quantity of dozens to

hundreds pieces, Vacuum casting or Silicone molding is the most economic way.Due to its fast turn over, low-cost, Vacuum casting or Silicone molding can greatly reduce the cost of product

development, cycle and risk.

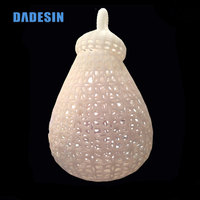

Silicone Mold materials are: domestic silica gel, imported silica gel, silica gel, silica gel.

The filling materials used: domestic and imported PU, POM, ABS, PP, PC high temperature resistant ABS