Contiunuous production waste tire pyrolysis plant

Quick Detail

- FOB Price : USD $200,000.00 / Piece

- Minimum order:1

- Place of Origin:China

Specifications

/

Contiunuous production waste tire pyrolysis plant

Continuous tire refining equipment

/

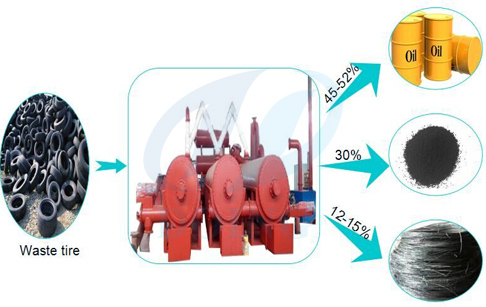

Contiunuous production waste tire pyrolysis plant

The advantages ofcontinuous tire refinery equipment

1.PLC control system, a high degree of automation.

2.24 hours of uninterrupted operation, continuous feeding, continuous discharge.

3. Low labor costs, only two workers can be.

4. large capacity, you can customize the capacity.

/

Continuous tire refining equipment

1. First collect enough waste tires to spare.

2. The waste tires into the wire drawing machine out of wire.

3. The extracted steel tire into the tire crusher, the broken tires into 3-5cm small pieces for feeding.

4. The broken tires are fed into a continuous tire cracker, heated and condensed at high temperature to obtain fuel. The residue of carbon black will eventually be discharged from the system.

The structure ofcontinuous tire refining equipment

/

Fuel oil application

1. Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, cement plants.

2. Carbon black: mainly used for pressure ball burning and refined milling. Which refined flour and can be used for new tires, rubber soles, pigment production materials.

3. Steel wire: mainly used for scrap recycling and re-casting.

Contact: Ms Bonnie

Phone: +86-371-5677 1821

Mobile/Wechat/Whatsapp:0086-135-2669-2320

Skype: bonniezhao2

Email:oilmachine@doinggroup.com

http://www.recyclingpyrolysisplant.com

http://www.doinggroup.com