Vacuum brazing diamond milling cutter machining various stones Alisa@moresuperhard.com

Quick Detail

- FOB Price : USD $50.00 / Piece

- Minimum order:1

- Place of Origin:China

- color:gloden

- material:diamond

- emial:Alisa@moresuperhard.com

- URL:www.moresuperhard.com

Specifications

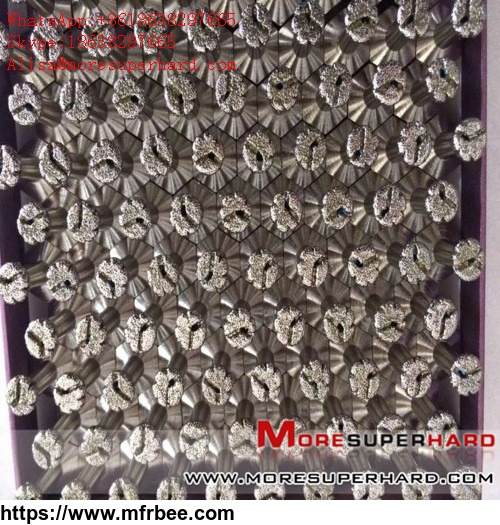

What is vacuum brazing?

Vacuum brazing refers to the workpiece heating in the vacuum chamber, which is mainly used for welding products with high quality and easily oxidized materials. The vacuum brazing furnace consists of pressure vessels with cylindrical side walls and doors, and the size and location of the doors are designed to seal one end of the cylindrical side walls. The workpiece handling system is mounted on the pressure vessel door to support the workpiece for heat treatment or brazing. The workpiece processing system includes a device for turning the workpiece during processing. The vacuum system can be connected to the workpiece so that the pressure inside the workpiece is lower than atmospheric pressure during the brazing process.

Advantages of vacuum brazing:

1. Vacuum brazing, without using solder, significantly improves the corrosion resistance of products, eliminates various pollution and pollution-free treatment equipment costs, and has good production safety conditions.

2. Vacuum brazing not only saves a lot of expensive metal solder, but also does not require complicated flux cleaning process, which reduces production cost.

3. The vacuum brazing solder has good wettability and fluidity, and can be used to weld more complicated and narrow channel devices.

4. Compared with other methods, the internal structure and clamping device of the furnace have a long life, which can reduce the maintenance cost of the furnace.

5. There are many materials suitable for vacuum brazing, such as aluminum, aluminum alloy, copper alloy, stainless steel, alloy steel, low carbon steel, titanium, nickel, Inconei, etc., which can be soldered in vacuum furnace. The designer determines the materials required according to the use of brazing devices, among which aluminum and aluminum alloy are most widely used.

Applicable fields:

1. All kinds of stone products

2. All kinds of ceramic products

3. Repair and grinding the outer circle molding and inner circle molding of glass products

Product features:

1. Sharp cutting

2. Long service life

3.It can be wet or dry

4. High production efficiency

Why choose our product

| Our product’s advantages: 1.High grinding efficiency |

| 2.Wonderful edge quality |

| 3.Long service life |

| 4.High polishing efficiency |

| 5.Large Exports |

| 6.Considerable after-sell service |

| 7.Amazing performance |

| 8.Various types and sizes available |

| 9.Direct Factory Manufacturer |

| 10.Backing/substrate material: Aluminum |

| 11.Abrasive layer: diamond |

| 12.Bond: vitrified |

| 13.Excellent cutting edges |

| 14.Reduced cycle times |

| 15.Custom Engineered |

/ /

/

If you have any questions, please contact us

WhatsApp:+8618638297665

Skype:18638297665

Alisa@moresuperhard.com

Tel:18638297665

URL:www.moresuperhard.com