Glass deep processing straight bilateral machine grinding edge consumables polishing wheel Alisa@moresuperhard.com

Quick Detail

- FOB Price : USD $50.00 / Piece

- Minimum order:1

- Place of Origin:China

Specifications

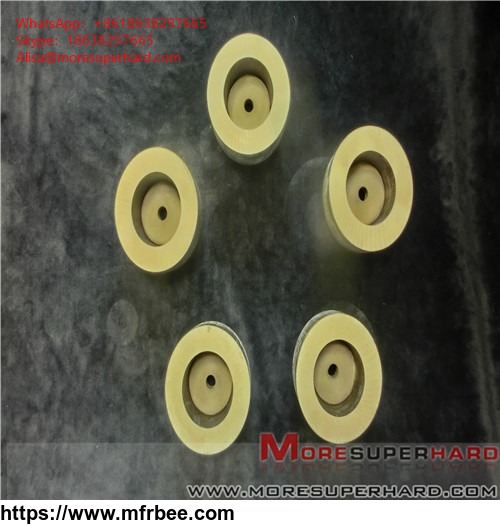

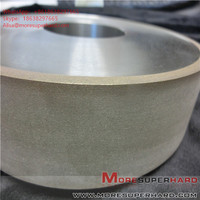

What is a polishing wheel

The polishing wheel is a kind of pressing plane wheel, which is formed by pressing several polishing wheel pieces together, and the outer surface of each polishing wheel piece is uniformly coated with a layer of polishing oil layer.There is no need to refuel separately during the polishing process.It is simple in structure and easy to use.

Application:

It is mainly used on straight-line machine, for polishing the bottom rim of glass, and cleaning oblique angle, also suitable for polishing oblique edge, round edge, duck beak shape edge and lacelike edge by one-arm and multi-arms machine.

| Glass Polishing Wheel | ||

| Dimension | Packing | |

| (inch) | (mm) | [pcs/kg/ctn] |

| 5\"×7/5\"×3\" | 130×35×60 | 50/25 |

| 6\"×7/5\"×3\" | 150×35×70 | 40/25 |

Type:

| 10S-I (Good Quality) | mainly used for polishing building glass whichdon\'t have high requirement for the polishing results. |

| 10S-II (Better Quality) | mainly used for polishing furniture glass whichhas high requirement for polishing brightness and effect. |

| 10S-III (Best Quality) | mainly used for polishing work piece whichrequires high brightness. It can replace Italy RBM wheel and popular in Europe market. |

Specification (mm):

| Name | Outer Diameter | Thickness | Inner Diameter | |

| 10S wheel | 10S40/60/80/120- hemline polishing wheel | 150 | 30, 35, 40 | 70, 50,22 |

| 10S arris pollishingwheel | 130 | 30, 35 | 60, 50, 22 | |

| 100 | 25, 30, 35 |

OEM size is available upon request.

Advantage:

1.A wide range of products, we can offer any consumable for glass deep-processing.

2.Advanced equipments from Germany and America to guarantee our product\'s

high

Quality.

3.Ex-factory available to keep customer’s lower cost.

4.Steady lead-time, 1~5 days for goods in

stock, and 7~15 days for goods through order

5.Various packages available, it depends on customer’s detailed requirements.

6.Shipping agent

available, to keep delivery in time.

7.Rich experience, to enable our products to be market all over the world.

8.Nice service, to get

satisfaction from our customers since the beginning to the end.

Feature:

1.High&stable quality

2.Long working lfe,no chipping

3.Wear-resistance,grinding efficiently

The selection of diamond tools in optical glass processing depends on the following factors

1.the shape of the processed optical glass components, brand, processing quality and processing technology .

2.According to the processing method and the precision of machine tools to select the shape, size and precision of diamond tools .

3.According to the remain of the machined workpieces and the roughness of the surface to select the particle size of diamond tools .

4.According to machining process and workpieces’ brand, especially for fine grinding and ultra-fine grinding to select the type of bonding agent .

5.According to the brand of processing optical components, the hardness and the brittleness to select the hardness and bond strength of diamond tools.