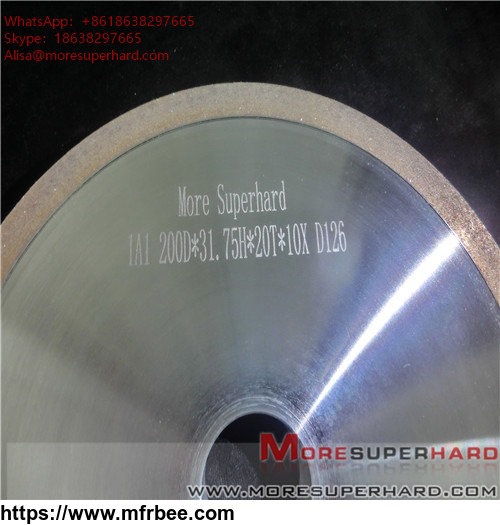

Metal - bonded diamond grinding wheel processing ceramics Alisa@moresuperhard.com

Quick Detail

- FOB Price : USD $30.00 / Piece

- Minimum order:1

- Place of Origin:China

Specifications

Description of metal bond diamond grinding wheel:

Metal Bond Diamond Grinding Wheels are long grinding life, fast stock removal, excellent interrupted grinding. They are recommended for grinding ceramic, glass and others.

Metal diamond grinding wheel consists of various types of alloys: copper, tin, silver, steel, cobalt, and tungsten. Metal diamond grinding wheel has excellent grinding ability as well as long tool life and is highly recommended for ceramics, carbide, and cermet.

metal bond diamond grinding wheel for grinding:The abrasive cloth mounted point is applicable to the grinding of inner hole of aluminum alloy steel cycle and the point that common flap disc cannot grind, rattan and timber product and the disposal of common surface grinding.

Brief introduction

The superhard grinding wheel made by diamond or cubic boron nitride (CBN) is a metal sintering wheel with bronze and other metals as the bond.Diamond grinding wheel is a special tool for grinding hard and brittle materials such as hard alloy, glass, ceramic and gemstone.

Standard dimensions

Diameter range:20-600mm

Thickness range:4-200mm

Grit size:1.5-426

Burning craft

More bronze and other metal as the binding agent, with high temperature sintering method, its high bonding strength, good molding, high temperature resistance, thermal conductivity and wear resistance, long service life, can bear a larger load.

Electroplating process

Advantages of electroplated diamond emery wheel: electroplating electroplating process is simple, less investment and convenient manufacturing;The surface is easy to use without repairing.The individual layer structure decides it can achieve very high working speed, at present the abroad already was as high as 250~300m/s;Although there is only one layer of diamond, it still has enough life.Electroplating is the only manufacturing method for precision roller and grinding wheel.

Soldering process

In order to give full play to the role of diamond, we should try to increase the control force of the binder on diamond and improve the bond strength of grinding wheel

| Brief Introduction | Diamond grinding wheels are mainly used for grinding and polishing stone products.such as Granite ,Marble, Sandstone, Limestone, etc.Also suitable for Grinding Concrete. Ideal for smoothing and shaping as well as stock removal. |

| Features | 1) Diameter: 100/115/125/150/180mm, other sizes upon request |

| 2) Grit: Coarse/medium/fine | |

| 3) Thread/ Connection: M12, M14, M16, 5/8-11, 22.23mm etc | |

| 4) Base & Matrix Material: aluminum or steel | |

| 5) Technology: Welding or Sintered | |

| 6) Type: Single row, Double rows, Turbo, T type etc | |

| Advantages: | 1) Durable metal and diamond compound |

| 2) Effective in the process of grinding and polishing concrete floor | |

| 3) Different colors and sizes as requested. | |

| 4) Competitive price and superior quality. |

Applicable processing materials:

1.Metal bonded diamond grinding wheel series: mainly used for processing quartz crystal, hard alloy, ceramic, glass, composite sheet, gemstone, ferrite, heat-resistant materials and thermal spraying workpieces

2.BCN series: mainly used to process high speed steels, tool steels, die steels, stainless steels and titanium alloys.

Our services

1. Quick Response: Your inquiry will be replied within 24 hours.

2. Competitive Price : Directly from factory to save your money.

3. after-sales warranty : Once there is problem after you received products, you can contact us in time. We will resolve it in short time.

4. Flexibility: Small orders are acceptable for quick delivery and to help you reduce stock cost.

5. OEM service: Custom fabrication according to your drawings ,samples or designs.

FAQ:

Q1. Can negotiate the price?

A: yes, you can. We will give some discount according to your quantity.

Q2. How can now my order’s production progress?

A: we will keep closely track the production and shipment progress. And we will inform you with the newest progress about producing and shipping.

Q3. How can you ensure your quality?

A: We have pass the ISO 9001:2008. If there is any problem with our products, please send me the detailed picture of the problem, once we verify it, we will change the products for you within 30 days.

Q4: When I contact you is suitable?

You can contact Us at any time, we promise that we will reply you within 12 hours.

A:So, please contact me for more information about our product, service and related issues.

If you have any questions, please contact us

Whats App:+8618638297665

Skype:18638297665

Alisa@moresuperhard.com

Tel:18638297665

URL:www.moresuperhard.com

To meet your requirements in every way, we need the following information

----- Shape and Dimension of the wheels

----- Grit size (Mesh, refer to Table#1)

----- Concentration

----- Bond(Resinoid, Vitrified, Metallic, Electroplated)

----- Quantity