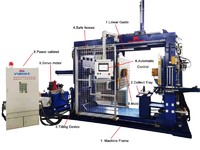

prompt delivery apg clamping machine for potential instrument transformer

Quick Detail

- Speed of clamping close(m/min):3.1

- FOB Price : USD $30,000.00 / Piece

- Minimum order:1

- Place of Origin:China

- Model No.:VOL-865

- Heating plate size (mm):800X600

- Clamping force (KN):250

- Machine dimension (mm):3750X970X2570

Specifications

|

Application-Standard APG clamping machine:

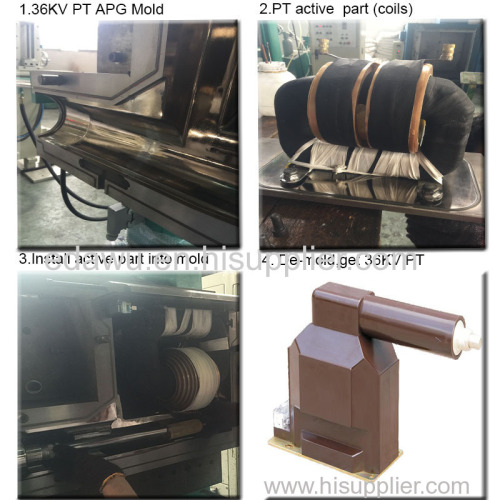

This APG casting machine belong to ,APG injection molding machinethe min clamp plate size is 600X800mm, and the Max clamp plate size is: 1200X1000mm, can meet production requirement from 11-36KV, such as current transformer, voltage transformer, insulator, bushing, spout, SFG gas-insulated indoor switch disconnector. Etc.

The APG casting machine upper and lower core distance can be customized, foundation pit is necessary if lower core travel distance above 500mm.

nstall and heating mould →Pre-mixing epoxy compound →Injection →Curing

Firstly,install mould on APG clamps →heat it up to 60°C→open mould, brush mould release agent →close mould

Secondly,pre-mixing casting compound in vacuum pot →turn off vacuum valve when vacuum gage show -0.1→release vacuum, push vacuum pot nearby APG machine→

Thirdly,APG Add pressure into vacuum pot and start injecting cast compound into mold, release pressure →open mold →take out products

Fourthly ,Curing. Move product in to oven.

| APG Claming Machine Production Process / APG machine work process / ·Products made by APG machine / · Dispatch APG Clamping Machine / | ||||

| | | | ||

| | | | | |

| | | | | |