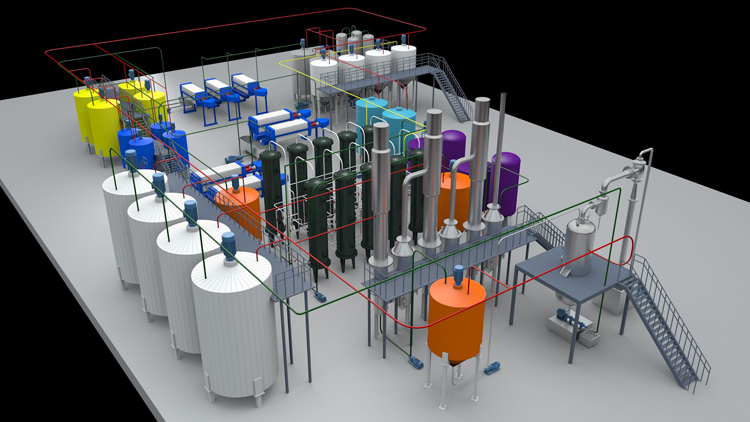

Rice maltose syrup processing machine

Quick Detail

- Minimum order:1

Specifications

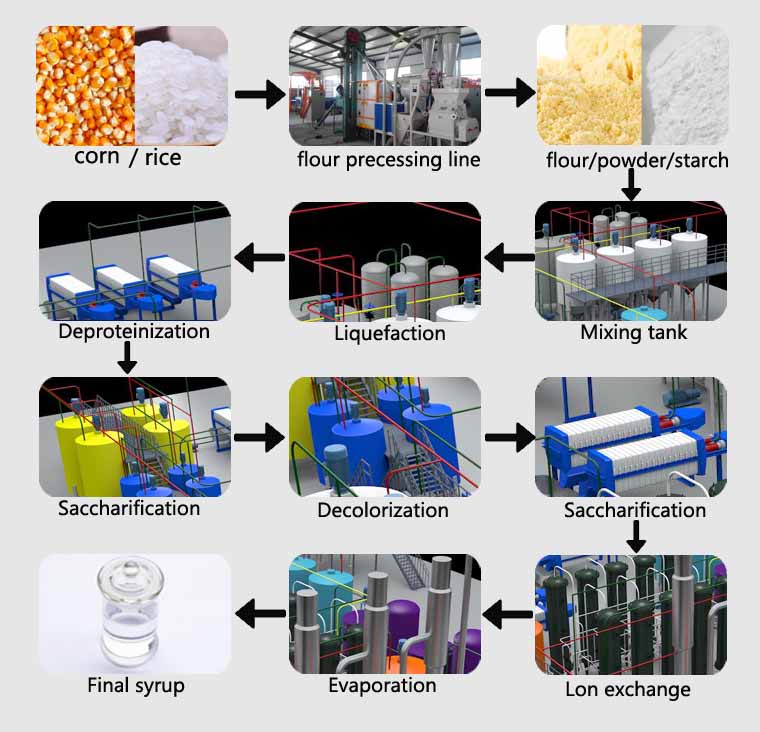

For automatic liquid syrup manufacturing plant process, we adopt enzyme method for starch hydrolysis, the raw material for liquid syrup manufacturing can be rice flour or all kinds of starch. Enzyme method now is the best choice for automatic liquid syrup manufacturing plant production, can guarantee fully hydrolysis starch, finished syrup high quality, transparent and high purity.

Our company technology process for the fully automatic liquid syrup manufacturing plant is as below:

/

Rice maltose syrup processing machine

1. Starch/rice flour preparation:

Process the raw grains into requests material which can be used for liquid syrup manufacturing. Requests starch/ rice flour clean, no paste, no putrefaction, free from admixture.

2. Starch slurry making process in liquid syrup manufacturing plant:

Mixing the starch and water to get the right density slurry. After mxing, get a sticky liquid, even stor stirring, the starch will not precipitated, the sent the liquid to the heating tank for softening. The heated starch milk is pumped to the jet cooker.

3. Liquefaction process:

The liquefaction process is used tp convert the starch which contented inside of the starch into liquid dextrin. The material will be sprayed at high temperature by jet cooker. With the aid of amylase enzyme and steam, the starch will be converted into liquid dextrin quickly. This is an important production procedure in automatic liquid syrup manufacturing plant.

4. Deproteinization process:

The deproteinization process aimed to separate the starch protein and other solid impurity from liquid dextrin by filter press to get a clean liquid. Then the liquid dextrin will be pumped to next part for further process in automatic liquid syrup manufacturing plant.

/

Maltose syrup processing technology

5. Saccharification:

The saccharification process is convert the liquid dextrin into required DE value glucose syrup with the aid of gluco-amylase in the tank. This process in the automatic liquid syrup manufacturing plant should be run under specific temperature for some hours. We can get the crude and yellow color liquid syrup.

6. Decolorization process:

The decolorization process is removing the color of the liquid syrup by activated carbon. The glucose syrup which reached required DE will be pumped from saccharification tank into the decolorization tank , mixed with activated carbon at proper temperature .

7.Decarburization process:

The decarburization process used in automatic liquid syrup manufacturing plant is for separating the activated carbon from the liquid syrup by filter press to get clear liquid syrup. The liquid syrup will flow into the slot and the transfer tank for next step.

8. Ion exchange process:

The Ion exchange process is using the resin to remove the tiny foreign items and bad odor to get high quality pure liquid syrup.

/

9. Evaporation:

The evaporation process is evaporate the water inside the liquid syrup to increase the DS of liquid syrup. Usually our automatic liquid syrup manufacturing plant adopt multi-effect evaporator and single effect evaporator work together for producing high DS liquid syrup.

10. Final product storage in liquid syrup manufacturing plant

The liquid syrup which reach the required DS in the evaporation process will be pumped into final product storage tanks for storage.The final product tank can keep the liquid syrup purity before transportation.

Fully automatic liquid syrup manufacturing plant consisting of:

Syrup melting vessel with mixing stirrer.

Basket filter & Transfer pump.

Syrup manufacturing vessel with stirrer.

Inline homogenizer.

Zero hold up filter press.

Storage tank with stirrer

Interconnecting pipeline.

Transfer pumps.

Integrated automatic control panel.

Working platform.

Fostered with immense years of industry experience and market understanding, we are offering automatic liquid syrup manufacturing plant. Our given product is distinguished among customers for its least maintenance. This product is available from us on numerous specifications so as to meet the variegated demand of clientele. Offered product is well developed using finest quality material and modern technology as per the set industrial norms.