grinding mdia forged steel balls, grinding forging media, forged steel balls

Quick Detail

- Minimum order:10

- FOB Price : USD $950.00 / Piece

- Place of Origin:China

Specifications

SteelBallForBallMillIntroduction

GAINCIN brand steel ball for ball mill, promise you high and even volume hardness, strong impact toughness and breaking rate less than 0.3% during bulk use./

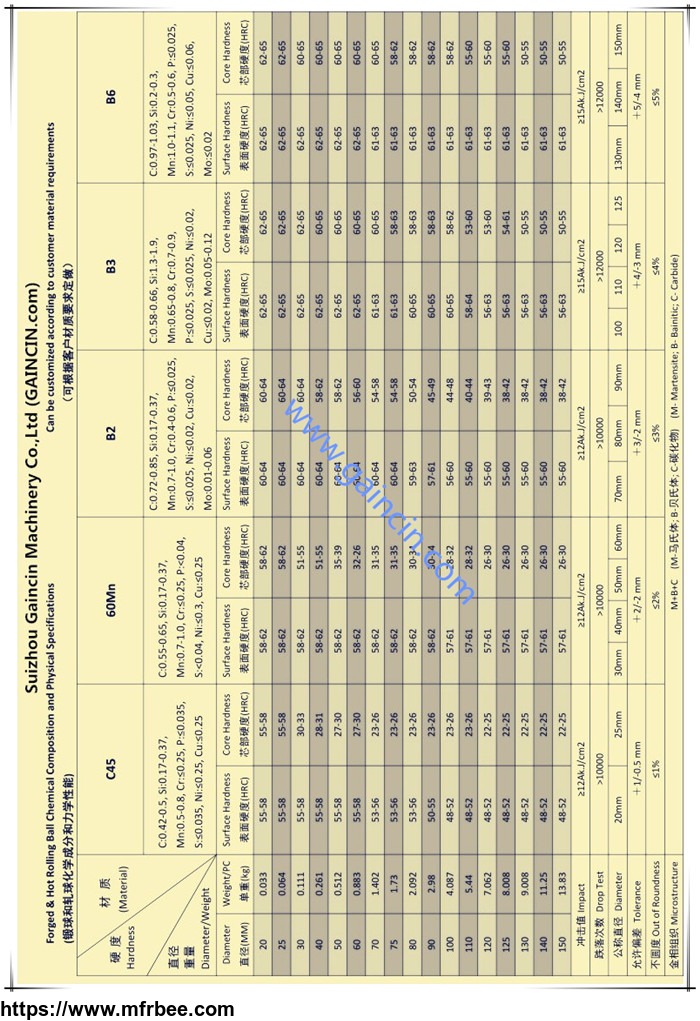

Technical Datas

Application:Steel Ball For Ball Mill for Iron ore mine, Gold Mine, Copper Mine, Silver Mine, etc.

Certification:ISO9001, ISO14001, OHSAS18001 etc.

Original:Hubei, China

Price:Negotiable

| Raw Meterial | Finished Ball Size | Single Ball Weight |

| Steel rod, 80mm | 125-126mm | 7800-8000 grams |

Payment term:TT, LC

Delivery date:Negotiable

Packing:export standard ton bag or Iron drum

Major Market:Middle East/ Africa/Asia/South America/Europe/North America

MOQ:50 tons (2x20’GP)

How we make Steel Ball For Ball Mill ?

/

Detailed explainations on above production flow on Steel Ball For Ball Mill:

1.Use step up heating furnace or induction furnace to heat on 80mm Dia steel rod;

2.Hot cutting machine cut the heated steel rod to fixed length we request;

3.Use magic hand to pick up cutted hot steel rod piece and feed to quick hammer machine;

4.Quick hammer machine hammer the cutted steel rod to a ball shape;

5.Use rolling machine to get round and smooth ball surface;

6.Cool the ball, then send into reheating furnace to reheat on ball to organize the microstructure of the steel ball;

7.Reheated ball will do the quenching treatment after cool to requested temperature;

8.The ball after quenching treatment, will send into tempering furnace, it will take 12 hours to finish the entire tempering progress on 125mm balls for complete stress relief;

9.Tempered ball will cool to room temperature on cooling plate, then do the export packing upon client’s request.

/

If you have special quality request on Steel Ball For Ball Mill, Please tell me, I am happy to develop the best Steel Ball For Ball Mill upon your unique request.

Quality control

1. Checking raw material before producing.

2. Testing production to find best bulk production method.

3. Quality checking 3-4 times during production per shift.

4. Have the random inspection before the delivery.

Address: no.1704,economic and technical

development zone,Suizhou,P.R.China

E-mail:Info@gaincin.com | Kimy.Lee@gaincin.com

Candy.Wu@gaincin.com

Tel: 86-722-358 8806

Fax: 86-722-358 8806 x 8002

Website: www.gaincin.com

Showroom:gaincin.bossgoo.com