forged steel grinding balls, grinding media forged balls, grinding ball mill media

Quick Detail

- FOB Price : USD $950.00 / Piece

- Minimum order:10

- Place of Origin:China

Specifications

Steel Balls For Ball Mill - “GAINCIN” brand steel balls for ball mill , your best choice for gold ore mine mineral processing, high and even hardness can support you to reduce ball consumption 10-20% based on win-win cooperation.

Technical Paremeters Applications: all of grinding media Steel Balls...

Technical Paremeters

Applications: Steel Balls For Ball Mill

Certification: ISO9001, ISO14001, OHSAS18001 etc.

Original: China

Price: Negotiable

Payment term: TT, LC

Delivery date: Negotiable

Packing: ton bag or Iron drum

Major Market: Middle East/ Africa/Asia/South America/Europe/North America

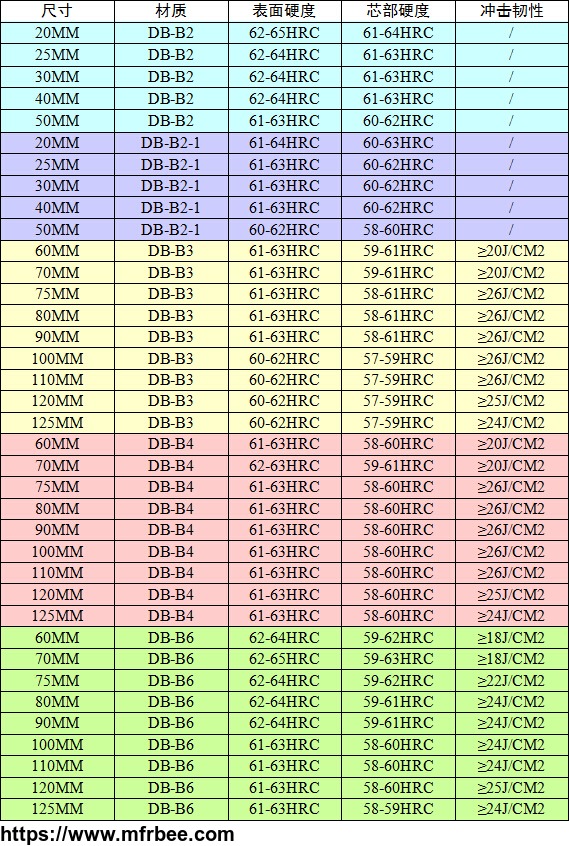

Ball Size: 25mm to 125mm (1” to 5”)

MOQ: 50 tons each size(2x20’GP)

Raw material: Alloy Steel rod

Difference between hot rolled grinding balls and casted balls:

1. Difference in density

As hot rolled grinding balls are based on round steel rod, which is produced by hot rolled extrusion of square billets. During the production of hot rolled balls, they are formed and extruded by rollers, so the density of hot rolled grinding balls is usually more than 7.89.

The casted balls, due to use of traditional casting process, it is hard to avoid pores and sand inclusions inside the casted balls and on the surface of them or casting trimming etc., so the density is usually around 7.45.

/

2. Difference is quality uniformity

As hot rolled grinding balls adopt finished round steel and have unified quality, the round steel will pass through natural gas heating furnace(or induction furnace), rolling machine, quenching system, tempering furnace, cooling plate and packing machine etc., in which a mechanized flow line operating mode has been achieved in the whole production process. The temperature, speed and technical parameters are controlled by computer tracking and ensure the production to be stable and uniform.

The steel scraps used for casted balls are likely to be uneven in material itself. Besides, the batching proportion of each furnace and casting speed are liable to influence of human factors and the quality of products is hard to keep stable.

/ 3. Difference in impact toughness and crus resistance

3. Difference in impact toughness and crus resistance

Due to high density and impact toughness≥18(J/CM2) of hot rolled grinding balls, the fatigue life of 6m height falling ball impact test is ≥ 20,000 times, so the breaking rate is quite lower.

Generally, the impact toughness of casted balls is ≤4(J/CM2) due to pores and sand inclusions, it cannot be performed with falling ball impact test, so it has a higher breaking rate risk.

/

Suizhou Gaincin Machinery Co., Ltd

Address: no.1704,economic and technical

development zone,Suizhou,P.R.China

E-mail:Info@gaincin.com | Kimy.Lee@gaincin.com

Candy.Wu@gaincin.com

Tel: 86-722-358 8806

Fax: 86-722-358 8806 x 8002

Website: www.gaincin.com

Showroom:gaincin.bossgoo.com