High-quality API Standard Drill Collar for Well Drilling

Quick Detail

- Minimum order:1

- Place of Origin:Shandong, China (Mainland)

- After-sales service provide:No overseas service provided

- Warranty:six months

- Certification:API

- Condition:New

- Color:Required

- Material:Carbon Steel

- Processing Type:Forging

- Machine Type:Drilling Tool

- Use:Well Drilling

- Processing Time:35 days

- Supply Ability:5000 pieces / per year

- Payment Terms:T / T; L / C; Western Union

Specifications

Drill collars are integral heavy-wall joints that are manufactured from a solid bar of modified alloy steel. The solid bars are quenched and tempered to obtain the mechanical properties, then trepanned drifted and threaded. All drill collars are heat-treated with hardness within 285 to 341 BHN, which are guaranteed one inch below the surface pipe.

Lake Petroleum could supply slick type drill collar, spiral drill collar and non-magnetic drill collar (NMDC).

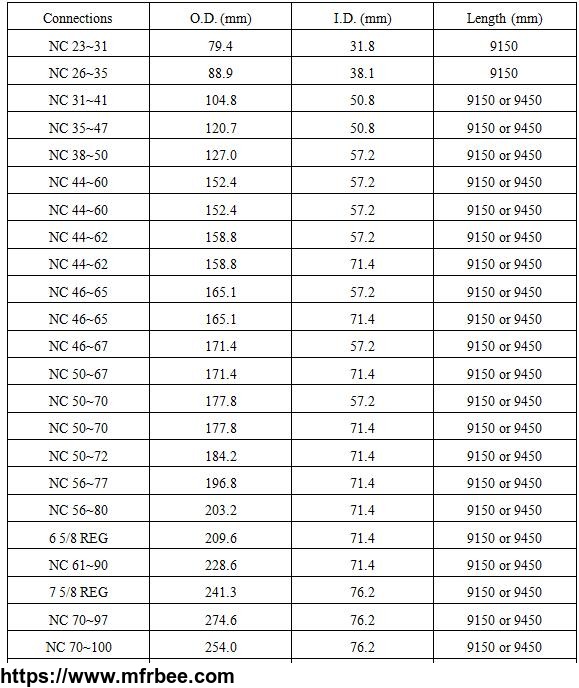

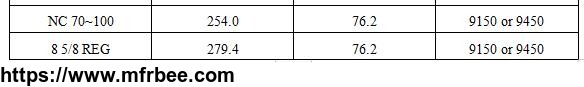

2. Main Technical Parameters:

/ /

/

3. Features:

(1). Hardness range of 285~341 BHN and a charpy impact value of 40 ft / lbs are guaranteed for evenly distributed 16 points in any cross sections at room temperature.

(2). Connections are phosphate coated father machining to protect the thread from corrosive elements and to prevent galling upon initial make-up. Thread roots are cold rolled on API and H0-90 connections.

(3). Pressed steel thread protectors are supplied to all drill collar that are equipped with standard connections.

(4). Manufactured strictly according to API standard.

(5). Widely used in oil, gas, HDD and geothermal field.

4. Connection:

All connections are precision-machined to API specification. API relief groove pin and bore back box stress relief are available on request. Thread roots are cold-worked to offer a greater resistance to fatigue. All connections are phosphate to minimize galling during makeup and applied with thread storage compound. Thread protectors are installed to ensure adequate joint protection during shipment.

Spiral Drill Collars:

The spiral cut is added to a drill collar to prevent the likelihood of different wall-sticking by reducing wall contact between the drill collar and the wall of the hole. The box end of the spiral collar is left uncut from 79 inches from box shoulder and the pin end is left uncut 30 inches from the pin shoulder.

5. FAQ:

Why you need to choose Lake Petro?

As a professional oil and gas service company, Lake Petro has many good experience in selling and serves for the oilfield industries for years. Quality is the culture of the company, we provide API and BV certified products for customer.

Can you make us the best quality products as well as a good price?

Yes,we can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us yourmoney will be safe.

What is special compare with other companies?

First, we provide the quality products, with BV and API certified; At the same time, we provide our customer with the best service after sale, any time any where.