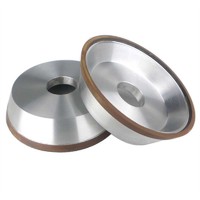

Surface Grinding Wheel

Ceramic Bond Diamond Grinding Wheel Surface Grinding Wheel Vitrified Grinding Wheel

Most commonly employed in the grinding of PCD and PCBN tools. Coastal Diamond vitrified grinding wheels have enabled polycrystalline tool fabricators to obtain excellent surface finishes, quickly and productively.

Vitrified grinding wheels can also be used in the fabrication of natural diamond, as well as many dense ceramic material. Be sure to contact us if you need help identifying if vitrified grinding wheels are right for your applications.

/

/

Feature

1.Eliminate Thermal Damage

Due to the excellent cutting ability, thermal damage to metal workpiece is eliminated. When a CBN wheel is used for grinding, compressive stress remains on the workpiece surface. Both strength and wear resistance are improved, in comparison to grinding with a conventional wheel.

2.Easy Automation

Since the minimization of changed in wheel shape reduces the need for dressing, automation is easier than when using a conventional grinding wheel.

3.High-Accuracy Grinding Possible

High-accuracy grinding is possible because there are minimized wheel wear and high rigidity.

4.Tough Materials Are Machinable

Even difficult-to-cut ferrous materials that cannot be readily grounded by diamond or conventional wheels, can be grounded by CBN wheels.

5.Cost Reduction Per Piece

The high grinding ratio reduces the wheel cost per workpiece. Savings are also produced by less frequent dressing/truing. Rejects and regrinding are both reduced due to high-accuracy.

Vitrified Diamond Grinding Wheels are mainly used for machining tungsten carbide, PCD, PCBN, ceramic, cermet, etc.

Vitrified CBN Grinding Wheels are mainly used for machining cast iron(alloy cast iron, chilled cast iron, nodular cast iron, etc.) steel(45#,55#,20Cr.etc.)

Package:

Diamond grinding wheels body usually aluminum, to make sure it safe, we use pearl cotton and carton box pack it separately, then put into carton boxes.

/

/

Applications

Automotive parts grinding

Paper Manufacturing Industry

Bearing Industry

Aerospace industry

Turbine Industry

Grinding of PCD and PCBN

Profile grinding of TC threading plates

OD grinding of Printing Rolls, Shafts and Rods

Flat grinding of Ceramic components

Flat, OD and ID grinding operations of various parts

Grinding of Camshafts and Crankshafts

Finishing of turbine parts

Products advantages:

1. Better peformance

2. Longer Working Life

3. Shorter Part Cycle Times

4. Reduced Machine Fatigue

5. Application-Specific Finishing

6. Made for Industrial Metals

7. Available in a variety of sizes

8. Safe and reliable