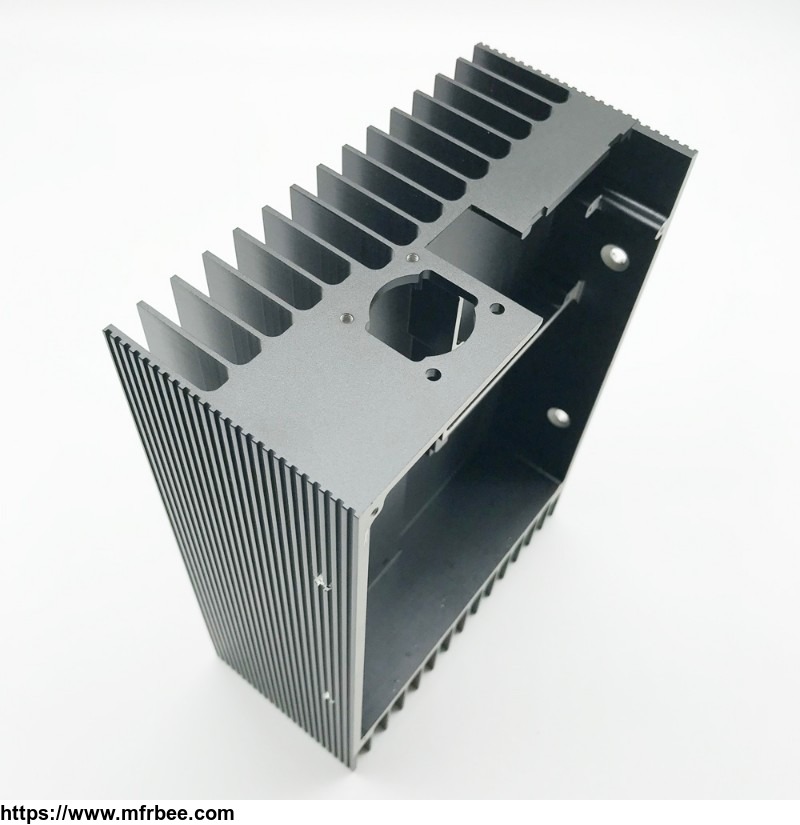

OEM CNC Parts Fabrication Precision Titanium Milled CNC Machining Part

Quick Detail

- Material:Plastic/ Metal/ Custom

- Certificate:ISO9001:2015/SGS/ROSH

- Quality Control:Full inspection

- Tolerance:0.02mm

- Product Name:Precision Aluminum Lathe CNC PartOEM CNC Parts Fabrication Precision Titanium Milled CNC Machining Part

- Place of Origin:China

- Minimum order:1

- Surface Treatment:Custom

- CNC Service:OEM CNC Parts Fabrication Precision Titanium Milled CNC Machining Part

- Payment Term:100% payment against shipment

- Price Term:EXW

- Drawing Format:PDF & STP file

Specifications

* OEM CNC Parts Fabrication Precision Titanium Milled CNC Machining Part

1) Key point: CNC Lathe Part,CNC Turned Part,CNC Milled Part,CNC Machining Part,CNC Stamping Part,CNC Cutting Part,CNC Casting Part,CNC Engraving Part,CNC Etching Part,CNC Mechanical Part,CNC

Drilling Part,CNC Iron Part,CNC Alloy Part,CNC Brass Part,CNC Metal Part,CNC Steel Part,CNC Bronze Part,CNC Copper Part,CNC Aluminum Part,CNC Titanium Part,CNC Carbon Steel Part,CNC Stainless Steel

Part,CNC Aluminium Part,CNC Plastic Part

2) Material: Metal/ Plastic/ Custom

3) Accuracy: +/-0.02mm

4) Certificate : ISO9001:2015/SGS/ROSH

5) CNC Service: CNC Milling/ CNC Drilling/ CNC Turning/ CNC Lathing/ CNC Cutting/ CNC Slotting,etc

6) Secondary Operations: Bending/ Brazing/ Cross Drilling/ Grinding/ Knurling/ Surface Grinding/ Tapping/ Threading/ Ultrasonic Welding/ Welding

7) Finishing Services: Anodizing/ Bead Blasting/ Hard Coat Anodizing/ Heat-Treating/ Heat Treating/ Laser etching/ Pad Printing/ Painting/ Parkerizing/ Plating/ Polishing/ Powder Coating/ Precious

Metal Plating

8) Other Services: Assembly/ Cam Design/ Cam Making/ Design Assistance/ Inspection/ Packaging/ Rapid Prototyping/ Reverse Engineering/ Tool Design/ Tool Grinding

9) Inspection: Full Inspection with 2D projector or other inspection equipments

10) Application Industry: Aerospace, Automotive, Medical, telecommunications, electronic, military, packing, Sensors, Optical instruments, computers,Motorcycles etc.

11) Customization: Available in various surface treatment and various materials.

12) To support in New Product Introduction, our experienced program managers are ready to accommodate any of your requirements.

13) We offer the total solution to customers’ idea with in-house production/assembly and outsourcing program

14) more than 10 years experience in the precision machinery field.