EV850-2S Walk behind laser screed machine(2m type)

Quick Detail

- Minimum order:1

- Place of Origin:China

- FOB Price : USD $10.00 / Piece

Specifications

| Power | |

| Power generation | 2.8 kw |

| Engine model | Honda GX200 |

| Engine type | Air-cooled 4-stroke OHV engine |

| Fuel consumption | 1.2-1.4L/hour |

| Operating Voltage | Single phase 220V--50AH |

| Fuel tank capacity | 14L |

| Laser control system | |

| Laser system control method | Microcomputer laser scanning |

| Laser system control results | Plane, slope, double slope |

| Laser control system | Leica, Switzerland |

| Walking system | |

| Walking mode | Reducer+Motor |

| Tire | Anti-solid narrow tire (inflatable wide tire) |

| Leveling head | |

| Type | Gravity self-balancing |

| Vibrating plate width | 2000mm |

| Vibration force | 500N |

| Vibration frequency | 4000 times / minute |

| Level adjustment | Leveling head self-adjusting |

| Size and weight | |

| Weight | 380kg |

Concrete laser screed machine Performance Characteristics

1.Intelligent operation by handle and easy to control, the machine can be operated by one person. It can freely move and turn with agility, allowing a running system controlled by hand. The wheels can go forwards, backwards and around with manually controlled speed.

2.Laser gun is installed separately , which makes it possible to do large area one-time construction while ensuring consistent ground level. The ground level will not be affected by the pattern plates, inducing no random error . Large area one-time construction will reduce joint place, thus lower the follow-up ground maintenance cost.

3.Integrated Leveling Head comprises scraper blade ,vibrator, vibrating plate, screw conveyor and other parts, combining working procedures of mixing, leveling, vibrating and etc, to complete the job in a row, so as to increase efficiency and reduce cost. It can keep level of the working surface even when the ground base is uneven with bumps and slope. Square end vibrating plate of 4000 times/min high vibration frequency will ensure concrete floors with great intensity and dispersed deformation strength ,thus effectively prevent the occurrence of floor bubble ,shell, cracking and unevenness.

4.The elevation is measured automatically by the laser measurement and control system; and the ground’s high point height is automatically controlled by the laser machine’s computer. Based on that, the ground can be more even by precision leveling directly on the concrete layer and the ground flatness will not be influenced by the pattern plates. Without having to be the formwork, the cost for material and labor as the working period will all get reduced. This machine can finish construction area of more than 300 sq. meters per hour. which means 3000-5000sq.meters per day.

The power system uses a Honda (Japan) engine with low failure rate and easy maintenance.

The integrated flattening head design, vibrating pulping and leveling are carried out simultaneously to improve work efficiency.

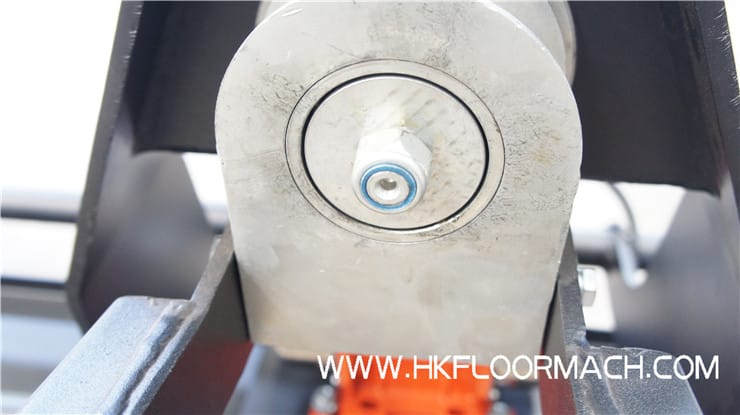

The connecting bearings are made of NSK (Japan) imported bearings to ensure long life and higher sensitivity.

Free off-road solid anti-strength tires can be used in concrete leveling conditions without reinforced mesh or thick mesh.

Free with vacuum wide tires, it can be used under the condition of finer mesh.

Rear support wheel for easy mechanical removal and movement.

The control panel is easy to operate and features a one-button auto-leveling function.