S940 Ride on concrete laser screed machine

Quick Detail

- FOB Price : USD $10.00 / Piece

- Minimum order:1

- Place of Origin:China

Specifications

Concrete laser screed

1.Intelligent operation by handle and easy to control, the machine can be operated by one person. It can freely move and turn with agility, allowing a running system controlled by hand. The wheels can go forwards, backwards and around with manually controlled speed.

2.Laser gun is installed separately , which makes it possible to do large area one-time construction while ensuring consistent ground level. The ground level will not be affected by the pattern plates, inducing no random error . Large area one-time construction will reduce joint place, thus lower the follow-up ground maintenance cost.

3.Integrated Leveling Head comprises scraper blade ,vibrator, vibrating plate, screw conveyor and other parts, combining working procedures of mixing, leveling, vibrating and etc, to complete the job in a row, so as to increase efficiency and reduce cost. It can keep level of the working surface even when the ground base is uneven with bumps and slope. Square end vibrating plate of 4000 times/min high vibration frequency will ensure concrete floors with great intensity and dispersed deformation strength ,thus effectively prevent the occurrence of floor bubble ,shell, cracking and unevenness.

4.The elevation is measured automatically by the laser measurement and control system; and the ground’s high point height is automatically controlled by the laser machine’s computer. Based on that, the ground can be more even by precision leveling directly on the concrete layer and the ground flatness will not be influenced by the pattern plates. Without having to be the formwork, the cost for material and labor as the working period will all get reduced. This machine can finish construction area of more than 300 sq. meters per hour. which means 3000-5000sq.meters per day.

/ /

/

/

/ /

/ /

/

/

/

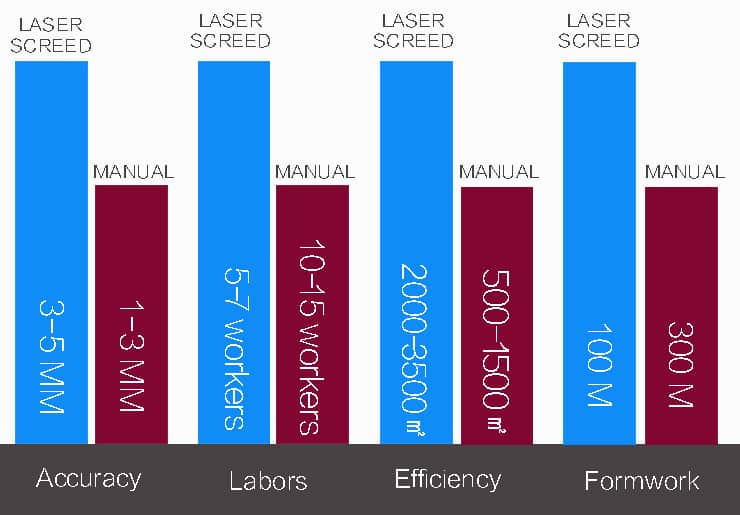

Comparison between HIKING laser screed and the traditional crafts

-

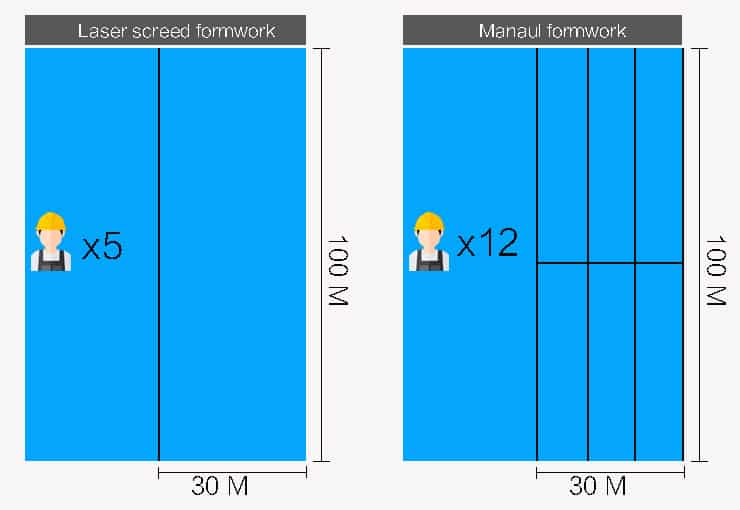

Reducing labor costs, improving efficiency doubled

Using traditional construction process needs more workers for supporting template (channel), RBI, paving, needing about 20 persons. The construction area per day is 800-1500㎡.

Using HIKING laser concrete screed can reduce the overall number of people to 4-8 persons. It can also be operated by one person. The construction area per day can be improved to 2000㎡—3500㎡, greatly reducing the labor costs.

-

Laser point-to-point, high-precision, low error.

Traditional craft leveling needs to support templates to control surface elevation and pull control line. Elevation error is larger. Entire levelness and flatness of the floor can not be guaranteed.

Using laser point emitter is applicable to disposable paving in a large area. The laser measurement and control system controls the elevation anytime, it does not need to pull the control line when leveling, it does not also need to support side templates to control ground level, thus avoiding the elevation error caused by template (channel) shock during the construction process, also reducing the elevation error caused by Traditional artificial block formworks.

/

-

Better flatness and integrity

Traditional construction process needs one day for formworks and one day for pouring mercury, so they can only jump for construction from one piece to another, there is a large limitation here they can not do continuous operation, and there exists a bad integrity and it is easy to cumulative errors in construction joints.

HIKING laser concrete screed will have a greater efficiency and flatness for the disposable overall paving with a large area of floor. The completion of the entire floor will make a better ground integrity. The traditional construction process can not complete this.

The ground will be even more dense and uniform.frequency vibrator of 4000 times per minute will let the vibrator of leveling head produce an uniform high frequency vibration to make even more dense concrete floor.

If you want to know more about this product, please visit Hiking\'s website https://www.hkfloormach.com/