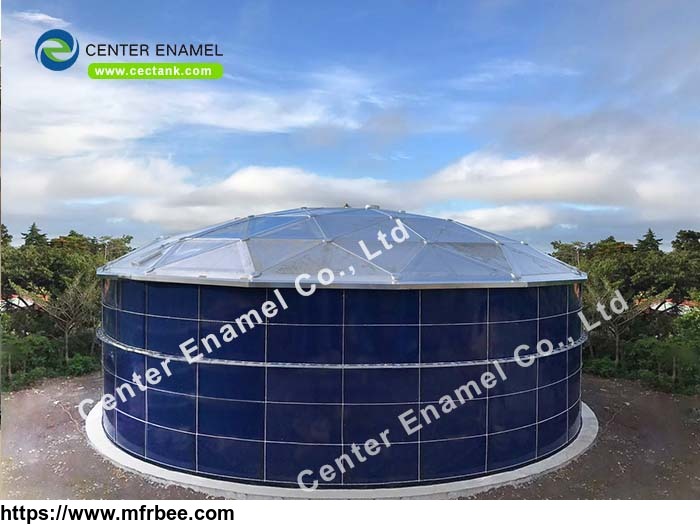

Center Enamel Provide Bolted Steel Biogas Storage Tanks With Single and Double Membrane Roofs

Quick Detail

- Minimum order:1

Specifications

Center Enamel providesbolted steelbiogas storage tanks design and manufacturing for the customer all over the world. Biogas storage systems are an active contribution to the generation of renewable energies, and thus to environmental protection in general. Biogas storage tanks are made from individual sections including steel plate, valves, doors or manhole covers, and membrane roofs. All the individual sections are manufactured and finished offsite, greatly reducing the time and labor involved in the field. Unlike conventional concrete or welded storage solutions, which require extensive fabrication and finishing processes onsite, bolted tanks offer quick installation, lower shipping costs, and they can be assembled in nearly any type of weather, eliminating many weather-related delays. This biogas storage design has been tested and proven over the decades and now is an integral feature in the design of any modern wastewater treatment plant worldwide.

How to assemble the biogas storage tank?

Once the site is prepared, the individual panels are erected, one layer at a time, starting from the bottom of the structure. Gaskets are fitted between adjoining panel sections, creating a strong seal and preventing damage to adjoining metal surfaces. The appropriate fasteners are subsequently installed and torqued to specification. Fittings such as valves, doors, or manhole covers are added as necessary, and finally, the tank\'s roof is installed.

Bolted Steel Biogas Storage Tanks Specifications

| Coating color | dark blue, dark green, white, and customized |

| A standard steel plate size | effective size 2400mm x 1200 m |

| Steel plates thickness | 3mm - 12mm, depends on the diameter & height |

| Coating thickness | 0.25mm - 0.4mm, two coatings internal and external |

| Acid and alkalinity proof | standard coating suits for PH3 - PH11, special coating suits for PH1 - PH14 |

| Adhesion | 3,450N/cm |

| Elastic | same as steel sheet, around 500KN/mm |

| Hardness | 6.0 Mohs |

| Service life | >30 years |

| Spark test | >1500 V |

| Permeability | gas and liquid impermeable |

| Easy yo clean | smooth, glossy, inert, anti-adhesion |

| Corrosion resistance | excellent! Suitable for wastewater saltwater, seawater, high sulfur crude oil, salt fox, organic and inorganic compounds |

Bolted Steel Biogas Storage Tanks Manufacturer

Center Enamel Co., Ltd is not only the first Glass-Fused-to-Steel Tanks manufacturer and supplier in China but also the most experienced Glass-Fused-to-Steel tanks manufacturer in all of Asia. Center Enamel Glass-Fused-to-Steel tanks engineering & design, product testing and quality system are in strict accordance with AWWA D103-09, OSHA, ISO/EN 28765, NSF61 and NFPA etc. international standards. CEC Glass-Fused-to-Steel tanks are widely used in drinking/potable water, industrial effluents, municipal sewage, bio-energy, landfill leachate, agriculture etc. applications. Until 2018, Center Enamel Glass-Fused-to-Steel tanks have been exported to more than 60 countries including USA, Australia, Canada, Malaysia, Indonesia, Russia, UAE, Panama, India and South Africa etc. The superior product quality and prompt service gain us worldwide recognition.