AOI Magnet Appearance Defect Inspection Equipment

Quick Detail

- Minimum order:1

- Place of Origin:China

- Usage:production quality control of NdFeB magnetic materials

- Detecting speed:400-550pcs/min

- Detectable defects:notches, indentations, maculas, chromatic aberrations, dirt,

- Overall size:1200*1200*1800mm(L*W*H)

- Overall weight:about 580Kg

Specifications

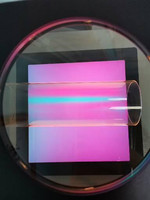

AOIMagnetAppearanceDefectInspection Equipment

Function

ThisAOIequipment (DE-DMM ) is an online defectinspection device formagnetic materials with high precision. It can automatically complete multiple functions of lens metal ring defect inspection, size measurement, automatic feeding, and automatic unloading. This equipment can quickly detect a variety of appearance defects, such as notches, indentations, maculas, chromatic aberrations, dirt, scratches, bubbles, convex hulls, etc. At the same time, it can also detect dimensions, such as verticality, parallelism, R Angle, length and width, thickness, etc.Moreover ,it is easy to connecttoproduction lines toachieve one-stop operation, improve production efficiency and save production costs.

Application

It is suitable for the production quality control of NdFeB magnetic materials.

Features

1. Minimum detectable defects :5um;

2. Glass turntable, multi-inspection positions;

3. Super bright LED unit provides maximum illuminance;

4. Automatic sorting of OK and NG materials;

5. Automatic feeding with vibrating plates, and automatic unloading withair blowing;

6.Data storage function for quality evaluation and process optimization;