Plastic Hose Clamps

Quick Detail

- FOB Price : USD $5,000.00 / Piece

- Minimum order:1

Specifications

The hose clamps plastic is new type structure fastener with strong mesh which is combined with various features of plastic and well-designed with precise tooth type structure to convert the acting

force by adjustment of appearance structure. The hose clip plastic is common used new type accessory for connection, fastening and sealing tubes, which can replace traditional fasteners such as

screw and nut, metal hose clamp and rope etc, and also with the advantages of easy fastening, strong force, good sealing, convenient disassembly, recycle and high cost performance.

Specification of Plastic Hose Clamps

Model No.

(New) Material Color Adapted Diameter

(mm) Product Width

(mm)

HG00001

POM

White 3.8-4.3 22

HG00004 4.3-4.8 22

HG00003 4.9-5.4 22

HG00029 5.5-6.0 22

HG00012 6.0-6.5 22

HG00002 6.5-7.0 23

HG00017 7.0-7.5 24

HG00007 7.5-8.0 24

HG00008 8.0-8.5 26

HG00022 8.6-9.1 26

HG00015 9.1-9.6 26

HG00009 9.6-10.2 25

HG00010 10.2-10.7 26

HG00019 10.7-11.2 25

HG00020 11.1-11.6 25

HG00011 11.6-12.1 24

HG00013 12.0-12.5 26

HG00021 12.6-13.1 28

HG00028 12.3-14.0 25

HG00018 13.1-13.6 33

HG00026 13.7-14.2 28

HG00030 14.2-14.7 27

HG00023 14.7-15.2 27

HG00024 15.2-15.7 27

HG00025 24.3-26.1 48

HG00031 35.5-37.5 51

Connection Steps of Plastic Hose Clamps

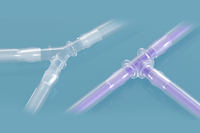

a. Connecting your tube fully into a connector

b. Use vernier calipers to measure the total diameter where you want to fix after tubing connected with connector (see above figure)

c. Choose a suitable model according to above-adapted Diameter listings

d. Slip the hose clamp until reaching the connector, then close the gear until it is tightly fastened

Disassembly Way of Plastic Hose Clamps

Clamp the outermost tooth with a wire-cutter(please don\'t clamp left and right tooth together), move flatly and gently as the tooth slot, fleetly twist it with small angle(upper and nether tooth

misplaced), then it will be loosened, Please note keep small angle when twisting to ensure the tooth non-deformed when misplaced it is reusable.

Solutions for Common Problems

1. Checking the fastening effect

Rotate the hose clamp manually to ensure it is tightly fastened with no blind side, good sealing and a smooth fastening surface.

2. Leakage and shed after pressured

a. Leakage after pressed includes many caused such as hose clamp with insufficient force, the diameter of the tube is far more than the outer diameter of the connector, a tube with insufficient

flexibility, etc.

b. Shed after pressured includes two causes: one is surpassing limit pressure of hose clamp with inner tooth prop up the outer tooth, multi-tooth lose common mesh (only rely on the main tooth);

another is the friction force between tube shed off (head part is still fastened). The solution is to choose the right specification or simultaneously use two pieces of hose clamps (head part

should be placed at two places, or it will be hard to disassemble)

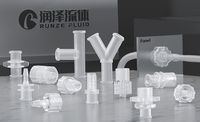

RUNZE FLUID, a professional microfluidic components supplier, offers a complete product range of microfluidic instrumental components including industrial syringe pumps, multiposition valves,

plastic fittings, peristaltic pumps, fluidic tubing, gastight syringes, OEM molding parts, which play an important role in fluid analytical instrument prototyping and production, like water, blood,

chemicals, diathermic oil, etc.