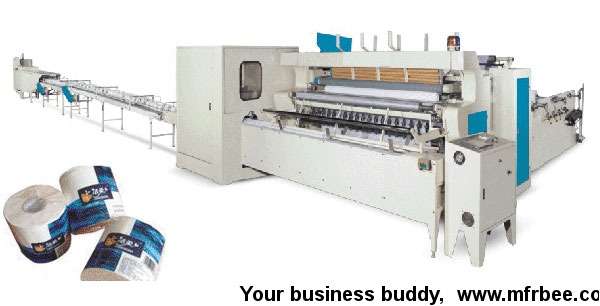

Automatic Toilet Paper roll Production Line (DC-TP-PL1092-2800)

Quick Detail

- Place of Origin:China(mainland)

Specifications

I. Introduction

Automatic Toilet Paper Production Line,Toilet roll Machine,toilet paper machine,toilet roll making machines,toilet paper manufacturing machine,toilet roll production plant,toilet

roll production line,kitchen towel roll production line,kitchen towel production plant

Model name: DC-TP-PL1092-2800

Model name: DC-TP-PL1092-2800

This machine is used to produce the toilet paper rolls and kitchen towel rolls as the picture shown above.

II. Function and Features

2. All the driven system to be by means of synchronous belts, nylon belts and gears, for years of free maintenance. Electrical eyes will be mounted on the different parts of the

line to monitor the machine and stop it in case it runs out of paper, cores or any other unforeseen problems. The lubrication systems will be provided on the major parts of the line.

3.The motor power is 30kW. Variable frequency control depending on the final specifications and requirements.

III. Technical Parameter

1. Jumbo roll width: 1700mm--2800mm

2. Dia. of raw material(mm): Up to Φ1500mm

3. Inner diameter of core: 76.2mm(other size, please point out)

4. Speed: 0-325m/min depending on model

5. Operating speed: 0-300m/min, 6 cycles(logs)/min

6. Finished roll outside diameter: toilet paper:Φ80-150mm

7. Finished roll outside diameter: Kitchen towel:Φ80-150mm

8. Perforation distance: Variable

9. Sheet count: Increments of one sheet

10. Inner diameter of core of finished product: Φ25-80mm

11. Raw material: 1 or 2 plies ,15-30g

12. Power: 30Kw~50Kw

IV. Export Details

1. Delivery time :80 days(Need time to promise the processing precision ,assembling precision ,of course if there is any special situation which needs shorter time ,it can be

discussed)

2. Load port: Xiamen port in Fujian Province

3. Packing: In standard export wooden cases

4. Contained in a 40,20 feet container (It depends on the quantity of the machines)

5. Machine installation and operation training: Seller will assign professional technicians and engineers to buyer’s plant to install the machine and train the workers .The round

air ticket, lodge and board fee, and salary will be on buyer’s side.

6. Warranty: One year(Except easy damaged parts), and will provide long term services including providing spare parts at low price and will heart and soul help the buyer to solve

any problem may occur.

7. Our company also provides the raw material to match with the machine.