Cargo Buckle Ratchet Straps China

Quick Detail

- Minimum order:1

- Place of Origin:Chongqing, China

Specifications

As an indispensable tool in logistics industry, cargo belt strap are designed for cargo control purposes to tighten and secure cargo/equipment on moving trucks, trailers, or any other

transportation facilities.

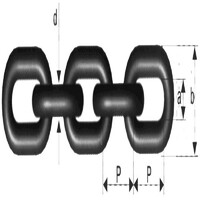

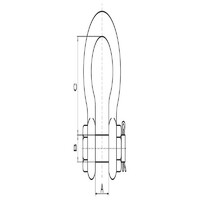

Structured with straps (one piece or two pieces), cargo buckle straps or cam buckles, and end fittings such as J hooks, S hooks, flat hooks, and other fittings to suit your application. As a

reliable material ratchet tie down manufacturers, TITANSUHE\'s ratchet strap belt features easy-of-use. One-hand fastening and a quick release mechanism enable a highly efficient tightening and

loosening to help you get the job done in short minutes.

Our ratchet tie down belt range from 1 inch ratchet straps up to 4 inch cargo straps in width and strength rating from 250kg up to 10ton. For less-intensive securing or bundling, our ratchet

lashing straps from 250kg up to 3000kg are available from cam buckle, and mini-ratchets to auto-retractable ratchets. With very competitive prices, they are your ideal choice for small cargo and

lightweight applications. Our lashing ratchet belt above 3000kg are designed for heavy duty applications during tougher transportation and tie-down jobs. They are coming with a double J hook,

Flat hook or D rings like that.

All our cargo tie down straps are made of industrial-grade stretch-resistant polyester webbing. This ratchet strap material is durable and hard-wearing. Ratchet buckles and end fittings are all

come with zinc plating or plastic coated (small size hook), they have good performance in weather and corrosion resistance, and can be used under temperature range between -40℃--+100℃

Cargo Lashing Strap Belt Applications

Trucks and Trailers: buckle tie down straps are commonly used to secure cargo on trucks and trailers. The straps can be attached to anchor points on the vehicle, such as D-rings or stake pockets,

and tightened using a ratchet or cam buckle. Cargo lashing straps can be used to secure a wide range of cargo types, including pallets, machinery, equipment, and vehicles.

Boats and Marine Transport: belt ratchet tie down are also used to secure boats and marine equipment during transport. The straps can be used to secure the boat to a trailer or a transport

vehicle, as well as to secure equipment and accessories on the boat. Marine-grade cargo lashing straps are typically made of materials that are resistant to saltwater and UV rays.

Air Cargo: tie ratchet strap are used in air cargo transport to secure cargo on pallets or containers. The straps must be certified to meet the standards of the International Air Transport

Association (IATA) and the Civil Aviation Authority (CAA).

Rail Transport: Cargo lashing straps are used in rail transport to secure cargo on flatcars or intermodal containers. The straps can be attached to anchor points on the railcar or container, and

tightened using a ratchet or tensioner.

Military and Defense: Cargo lashing straps are used by military and defense organizations to secure cargo and equipment during transport. Military-grade cargo lashing straps are typically made of

materials that are resistant to abrasion, weather, and extreme temperatures.

DIY Projects and Home Use: Cargo lashing straps can be used for a variety of DIY projects and home use, such as securing furniture, appliances, or camping gear during transport. They can also be

used to create a makeshift hammock or to secure a load on a roof rack.

Ratchet Cargo Belt Using tips

Ratchet cargo belts, also known as ratchet straps, are a popular and effective tool for securing cargo during transport. Here are some tips for using ratchet cargo belts:

Inspect the Belt: Before using a ratchet cargo belt, inspect it for any damage or wear. Check for cuts, tears, fraying, or any other signs of damage that could compromise the strength and

durability of the belt. If you notice any damage, do not use the belt and replace it with a new one.

Choose the Right Belt: Select the appropriate ratchet cargo belt for the weight and size of the cargo you are transporting. Check the load capacity of the belt and make sure it can handle the

weight of your cargo. Use wider belts for heavier loads and narrower belts for lighter loads.

Use Proper Anchors: Make sure the anchors you attach the ratchet cargo belt to are strong enough to withstand the weight and force of the cargo. Use anchor points that are specifically designed

for cargo transport, such as D-rings, stake pockets, or tie-down points.

Properly Position the Belt: Position the ratchet cargo belt over the center of the cargo and secure it to the anchor points on either side of the cargo. Make sure the belt is not twisted or

tangled and that it is positioned evenly over the cargo.

Tighten the Belt: Use the ratchet mechanism to tighten the belt until it is snug against the cargo. Be careful not to over-tighten the belt, as this can damage the cargo or the belt itself.

Tighten the belt evenly on both sides of the cargo.

Check the Belt Regularly: Check the ratchet cargo belt regularly during transport to ensure it remains tight and secure. Re-tighten the belt if necessary, and check for any signs of damage or

wear.

By following these tips, you can effectively use ratchet cargo belts to securely transport your cargo and avoid any damage or accidents during transit.

How To Use Car Ratchet Straps

The hooks of the cargo buckle custom tie down straps should be fixed on both sides of the truck.

Pull the handle, and the ratchet wheel will working accordingly, then the ratchet tie down belt will gradually tighten up, to achieve the purpose of bundling goods.

When unload, pull the handle of hand puller, rotate the handle, gradually release the tension. Until the cargo lashing strap belt is in a relaxed situation, then you can unload the hooks of both

sides and unload the goods.

What Is A Ratchet Strap Used For

A ratchet strap, also known as a tie-down strap or lashing strap, is a type of strap used for securing cargo during transportation. It consists of a long, narrow strip of strong and durable

material, such as polyester or nylon, with a ratchet mechanism at one end and a hook or loop at the other end.

Ratchet straps are commonly used to secure cargo on trucks, trailers, and other vehicles to prevent it from shifting or falling during transport. They are also used to secure items to racks,

posts, or other fixed objects. Some common uses of ratchet straps include:

Securing furniture: Ratchet straps are commonly used to secure large and bulky furniture items, such as couches, chairs, and mattresses, during transportation.

Tying down motorcycles: Ratchet straps are used to secure motorcycles to trailers or trucks to prevent them from falling or shifting during transport.

Securing building materials: Ratchet straps are used to secure building materials, such as lumber, pipes, and drywall, during transportation to prevent them from falling off or damaging other

items.

Securing equipment: Ratchet straps are used to secure heavy equipment, such as lawnmowers, generators, and power tools, during transportation to prevent them from moving or shifting.

Tying down boats: Ratchet straps are used to secure boats to trailers or docks to prevent them from falling or moving during transport or storage.

In summary, ratchet straps are used for securing cargo during transportation. They are commonly used for securing furniture, motorcycles, building materials, equipment, and boats. Ratchet straps

are an essential tool for ensuring the safe and secure transportation of goods.

Cargo Ratchet Belt Features

Cargo ratchet belts, also known as cargo tie-down straps, are designed for securing cargo during transportation. They are available in various lengths and widths, and with different weight

capacities to suit different applications. Here are some of the key features of cargo ratchet belts:

Ratchet mechanism: Cargo ratchet belts use a ratchet mechanism to tighten and secure the strap around the cargo. This mechanism allows for precise tensioning and ensures a tight and secure hold

on the cargo.

Durable material: Cargo ratchet belts are made of durable materials such as polyester or nylon webbing that can withstand heavy loads and resist damage from exposure to sunlight, moisture, and

chemicals.

Hooks and anchor points: Cargo ratchet belts are equipped with hooks and anchor points that allow for easy attachment to anchor points on the cargo or the vehicle. These hooks and anchor points

are usually made of high-strength steel and are designed to withstand heavy loads.

Easy release: Cargo ratchet belts feature an easy-release mechanism that allows for quick and easy release of the strap tension after use. This mechanism is usually a lever or button that

disengages the ratchet mechanism and releases the tension on the strap.

Adjustable length: Cargo ratchet belts are available in different lengths, and most models allow for easy adjustment of the length to suit different cargo sizes and shapes.

Safety features: Many cargo ratchet belts come with safety features such as locking mechanisms that prevent accidental release of the tension, and reflective strips that increase visibility in

low light conditions.

In summary, cargo ratchet belts are designed for securing cargo during transportation and feature a ratchet mechanism, durable material, hooks and anchor points, easy release mechanism,

adjustable length, and safety features. These features make cargo ratchet belts a reliable and safe tool for securing cargo during transportation.

Ratchet Strap Material

Ratchet straps are made of different materials, depending on their intended use and weight capacity. The most common materials used for ratchet straps are polyester, nylon, and polypropylene.

Polyester is the most commonly used material for ratchet straps. It is a strong, durable material that can withstand heavy loads and resist damage from exposure to sunlight, moisture, and

chemicals. Polyester straps have a low stretch rate, which means they maintain their tension and hold the load securely in place.

Nylon is another popular material for ratchet straps. It is also strong and durable, with good resistance to abrasion and impact. Nylon straps have a higher stretch rate than polyester, which

allows them to absorb shock and reduce the risk of damage to the cargo during transport.

Polypropylene is a lightweight, economical material used for lighter loads. It has good resistance to moisture and chemicals but is not as strong or durable as polyester or nylon. Polypropylene

straps are often used for securing smaller or less valuable items during transport.

In summary, ratchet straps can be made of polyester, nylon, or polypropylene. Polyester is the most commonly used material due to its strength, durability, and resistance to damage. Nylon is also

a strong and durable option but has a higher stretch rate. Polypropylene is a lightweight and economical option for lighter loads. The choice of material depends on the load weight, transport

conditions, and budget.