Flat Wire & Honey Bomb Conveyor Belt

Specifications

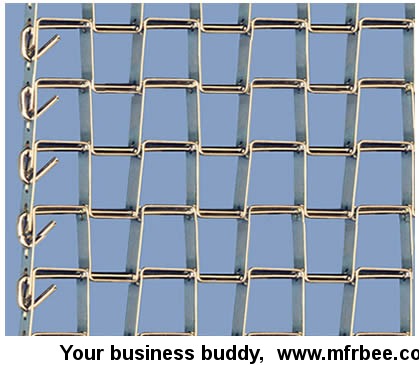

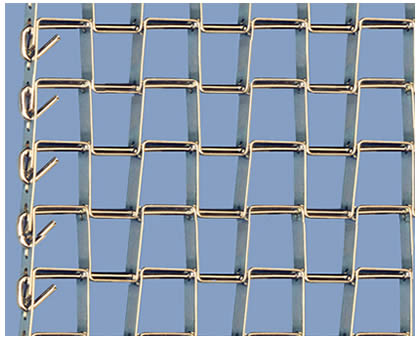

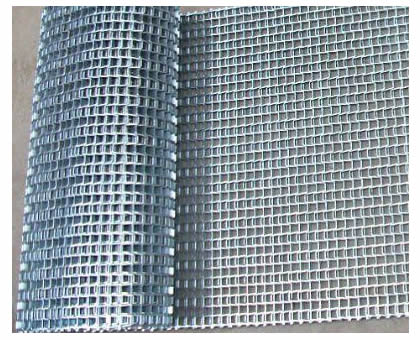

Flat Wire Conveyor Belts - Clinched Edge & Weld Edge

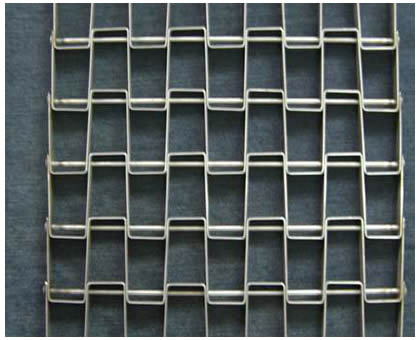

Flat wire conveyor belts, constructed of cross rods and flat metal strips, can provide an open mesh with flat surface, endless splicing, easy air circulation, excellent fluid drainage as well as ease of cleaning. Meanwhile, they are easy to maintain just replacing the section that is damaged or worn down.

Two styles of belt edges:

The selvages the flat wire conveyor belts are available in clinched edge and welded edge as shown in the picture:

Clinched edge

Welded edge

Features:

- Large open area for excellent air circulation.

- Optional side plates, reinforcing links and flights.

- Strong edge avoids snagging or catching even there are conveyor protrusions.

- Low maintenance.

- Suitable for friction or sprocket drive.

- Anti-slipping and last for years if used well.

- Durable structure prevents belt from deforming under heavy loads.

Application:

- Food baking, cooling and freezing, etc.

- Chemical industry.

- Agricultural farming and harvesting.

- Being used in discharging tower at ports.

- Sorting, sieving and waste handling system.

- Washing, drying, painting and transferring.

- Acting as matting and drag mats.

Details:

- Material: C-1045, C1050 high carbon steel, low carbon galvanized steel, stainless steel 201, 304, 316, etc.

- Open size: 1" × 1", 1/2" × 1", 1/2" × 1/2".

- Belt width: 50mm to 3500mm.

- Belt speed: from less than 1 m/min to 25 m/min.

- Temperature range: -30°C to 400°C.

- Accessories: flight clips, lane dividers, edge guards or pin up attachments, etc.

Specification:

The description of flat wire conveyor belts is followed by its load capacity. Normally, there are standard duty belts and heavy duty belts for our customer to choose from according to their different needs. The standard duty type is sufficient for most applications and heavy duty type is ideal for heavy product conveying and some tougher conditions.

As your request, radius flat wire conveyor belts can also be supplied with right and left turn up to 180 degrees and reinforcing links to strengthen the outside edges of the belt. Its turning ability makes the belt capable to operate in limited space without obstacles and troublesome transfers.

| Styles | Types | Mesh size | Belt width | Cross rod diameter | Flat strip (Height × Thickness) | Tension (max) | Approx. weight |

|---|---|---|---|---|---|---|---|

| Standard duty & clinched edge | FWSC-1 | 1" × 1" | 4.5" to 240" | 0.105" | 3/8" × .046" | 480 lbs./ft | 1.85 lbs./square feet |

| FWSC-2 | ½" × 1" | 4.125" to 240" | 0.105" | 3/8" × .046" | 660 lbs./ft | 2.20 lbs./square feet | |

| FWSC-3 | ½" × 1" | 4.125" to 240" | 0.105" | 3/8" × .046" | 660 lbs./ft | 2.50 lbs./square feet | |

| FWSC-4 | ¾" × 1" | 4.5" to 240" | 0.12" | 3/8" × .046" | 550 lbs./ft | 2.00 lbs./square feet | |

| Standard duty & welded edge | FWSW-1 | 1" × 1" | 3" to 240" | 0.105" | 3/8" × .046" | 480 lbs./ft | 1.85 lbs./square feet |

| FWSW-2 | ½" × 1" | 3.25" to 240" | 0.105" | 3/8" × .046" | 660 lbs./ft | 2.20 lbs./square feet | |

| FWSW-3 | ½" × ½" | 3" to 240" | 0.105" | 3/8" × .046" | 750 lbs./ft | 3.25 lbs./square feet | |

| FWSW-4 | ½" × 1" | 3.25" to 240" | 0.12" | 3/8" × .046" | 660 lbs./ft | 2.50 lbs./square feet | |

| Heavy duty & clinched edge | FWHC-1 | 1" × 1" | 10" to 192" | 0.192" | 1/2" × .062" | 1350 lbs./ft | 3.55 lbs./square feet |

| FWHC-2 | ½" × 1" | 10" to 192" | 0.192" | 1/2" × .062" | 1750 lbs./ft | 3.55 lbs./square feet |

Tips:

Don't forget to take size and weight of load in to consideration when purchasing a flat wire conveyor belt.

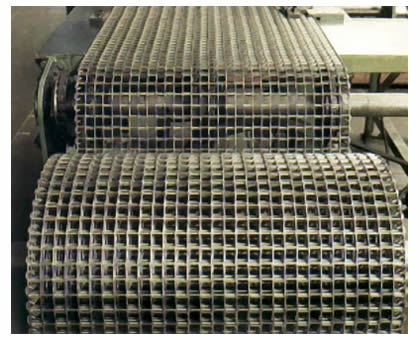

Manufacturing process of flat wire conveyor belt

A roll of steel flat wire conveyor belt