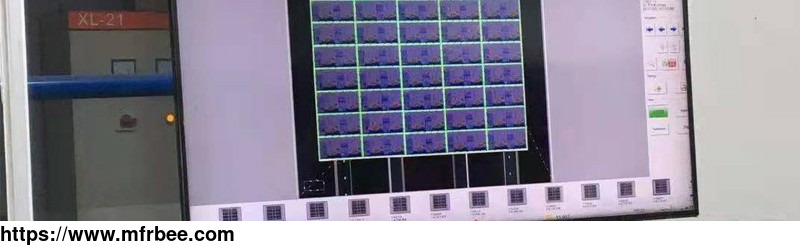

Metal Printing and Coating Online Production Line Monitoring

Quick Detail

- FOB Price : USD $2,000,000.00 / Piece

- Minimum order:1

- Place of Origin:china

Specifications

The production line monitoring technology is suitable for metal decorating printing and coating production line, which greatly improves the yield and reduce metal sheets waste. Metal sheets are an

expensive material and early detection of damaged coating and contaminated margin reduces ma-chine stops and waste cans in welding lines. The production line monitoring system ensures short setup

times and increases production efficiency – start the print run with 100 % defect-free material.

Production Line Monitoring Speeds Up Production

A production line monitoring solution can do the following to speed up production with 100 % Pre-Press Coating Control:

Remove damaged sheets before the decoration process starts

Automatic measurement of dimensions during setup and production

Prevent misregistration defects with in-line margin detection

Production Line Monitoring Improves Efficiency

A production line monitoring system can do the following to improve efficiency in metal sheet decoration:

Reduced machine setup time

Early alarms prevent evolving defects

Eject waste sheets within configurable defect parameters

Restored job requirements enable fast machine-ready

Metal Printing Press and Coating production line monitoring Strengths

100 % Quality Control Throughout Entire Metal Packaging Production.

The production line monitoring can maximize yield while exceeding customer expectations.

100 % Quality Inspection Supports Faster ROI.