Ampoule Breaking Tester Medical Packaging Tensile Testing Instrument

Quick Detail

- Minimum order:1

- Place of Origin:China

Specifications

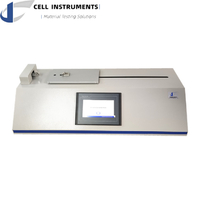

BST-01 Ampoule Breaking Tester

Background

Ampoules are commonly used to store pharmaceutical substances. They are sealed hermetically by melting the thin top using an open flame. The neck of the ampoule is usually designed to be snapped

off for easy access to the contents. The breaking force of the neck is a critical factor as it affects both the safety of the pharmaceuticals inside and their clinical application.

Application

An Ampoule Breaking Strength Tester is designed to quantitatively test the breaking strength of ampoules. This equipment is used to measure how much force is required to break the ampoule neck.

Standards

Several standards govern the testing of ampoule breaking strength, ensuring consistency and reliability in the testing process. ISO 9187, GB 2637, YBB00332002

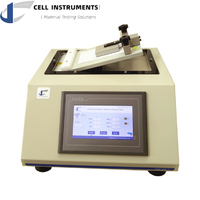

Test Process

An ampoule sample is place on the fixtures and the pressing head is driven down by the power system at the speed of 10 mm/m. The breaking strength is detected by the high precision load cell when

the pressing head touches ampoule neck and breaks it.

Technical Features

BST-01 Ampoule Breaking Strength Tester is a highly versatile and advanced piece of equipment with a wide range of applications in the pharmaceutical and medical sectors. Its technical features,

including constant rate of displacement, industrial-level stability, PLC control, stepper motor precision, and safety measures, make it a valuable tool for various testing needs beyond ampoule

breaking strength, such as such as compression, cap opening, syringe gliding force, puncture, stopper penetration etc.

The device\'s standout features encompass a PLC control unit, an HMI touch screen, and a stepper motor with a precision ball-lead screw for precise speed control. Safety is prioritized through

features like a collecting tube for broken samples and a protective cover for samples that may jump during testing.

Below are additional characteristics:

1.Test fixtures in varying capacities: 1ml, 2ml, 5ml, 10ml, and 20ml, accommodating different specifications.

2.Availability of multiple fixtures for testing various materials used in medical packaging.

3 .Incorporation of a limiting device and an automatic return function.

4.Adjustable test speed to suit different requirements.

5.Equipped with a dot matrix microprinter.

6.Provision of a protective cover.

7.Optional inclusion of RS 232 connectivity and professional software.

Main Parameter

Test Range 0~200N (Or as required)

Speed 1~500mm/min

Resolution 0.1N

Accuracy 0.5% F.S.

Power 110~ 220V 50/60Hz