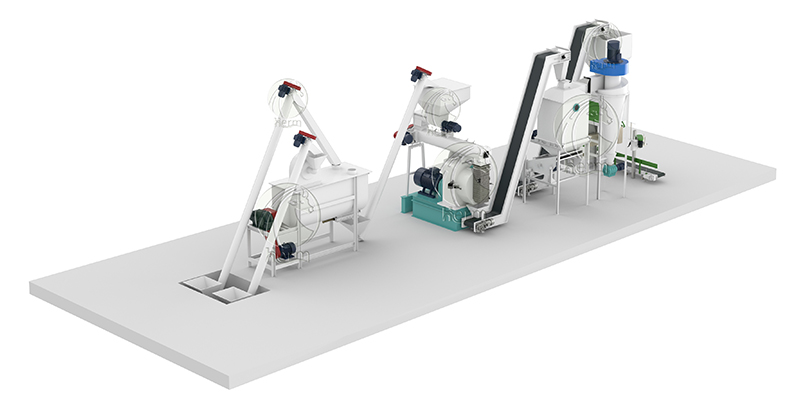

1-2T/H Feed Pellet Line

Quick Detail

- FOB Price : USD $2,000.00 / Piece

- Minimum order:1

- Place of Origin:China

Specifications

Some Questions About the 1-2T/H Feed Pellet Line

1. Who is suitable for this 1-2t/h feed pellet production line?

This animal feed production line is specially designed for small farmers, small animal farm plants, and animal feed suppliers who enter the feed production industry for the first time, etc.

2. What raw material can be used in the 1-2t/h feed pellet production line?

The raw materials of the animal feed pellet production line include corn/corn, wheat, grass, alfalfa, oil cake, pasture, bone meal, trace elements, and other raw materials. Such as premix, vitamins, wheat bran, salt, etc. Different formulas can be made according to your different formulas and the needs of farmed animals.

3. Why Choose Our Animal Feed Production Line?

Wide application: This animal feed pellet factory can make feed for poultry, livestock, sheep, pigs, cattle, chickens, ducks, fish, shrimp, crab, aquatic, and other animals. It can make pellets with a diameter of 1-12mm. The diameter of the feed pellet can be changed by adjusting the mold of the feed pellet. It also can produce mash and crumble.

Small Investment: the compact design of this small feed mill plant can reduce the investment in workshops, etc.

Low Installation Cost: Our feed production line comes with detailed installation and commissioning instructions, it is easy to install the machine, and you can use it immediately after the machine is installed.

Low Production Cost: The animal feed factory only needs 1-2 production workers to complete the production operation. With less labor and lower production costs, your profits will increase.

4. What kind of animal feed pellet production line produce?

This feed pellet production line can produce feed for meat chicken, broilers, laying hens, small baby chicken feed, cattle feed, pig feed, duck feed, sheep feed, poultry feed, livestock feed, goat feed, fish feed, shrimp feed, crab feed, aquatic feed, etc. Such as 2-4mm diameter chick feed pellets and pig feed pellets. 2-5mm rabbit feed pellets, 4-8mm cattle or sheep feed pellets.

This feed pellet mill with a ring die, makes pellets of 1-12mm in diameter, the pellet size can be changed with our feed pellet machine by adjusting the die. It also can produce mash and crumble.

5. What we can do for you?

We can provide the project design, flow chart, feed-making machine manufacturer, project installation and commission, staff training, after-sales service, etc. Also, our professional install team will serve you if you need it.

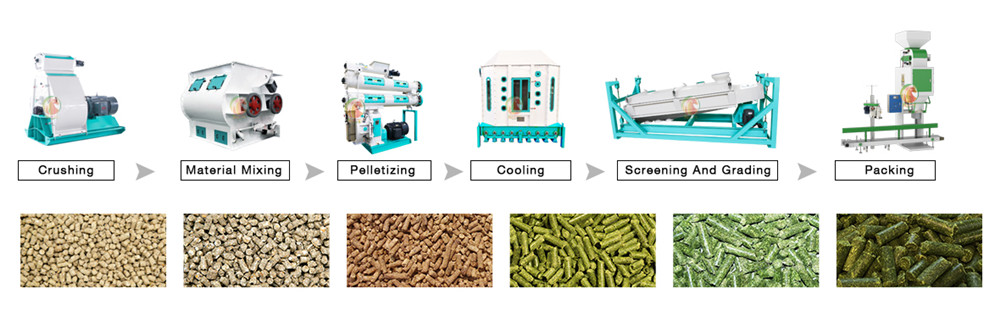

What is The Complete Animal Feed Pellet Production Line Working Process ?

Feed Pellets Processing Technology

Raw Material → Feed Grinding → Feed Mixing → Feed Pelletizing → Pellet Cooling → Pellet Crushing → Screening & Grading → Pellet Packing

1. Storage of the raw materials

1. Storage of the raw materials There are many different raw materials and materials in the feed, so various types of silos must be used. There are three types of silos that can be used in the feed pellet line, such as hopper silo, flat bottom silo, and galvanized silo.

2. Cleaning of raw materials

Impurities in feed raw materials not only affect the quality of feed products but also directly affect the use of feed processing equipment and the personal safety of staff. In severe cases, the entire equipment will be damaged and the smooth progress of feed production will be affected. Therefore, impurities in the feed raw materials should be removed in time.

3. Crushing of raw materials

The technological process of feed crushing is determined according to the required particle size, feed variety, and other conditions. The number of raw materials crushed can be divided into the primary crushing process circulating crushing process, or secondary crushing process. The combination with the batching process can be divided into the first batching and then crushing process and the first crushing and then batching process.

4. Batching process

The rational design of the batching process is to correctly select the specification and quantity of the batching metering device so that it is fully coordinated with the combination of batching feeding equipment, mixing units, and other equipment.

5. Mixing process

The mixing process refers to the technological method and process of weighing the ingredients in the feed formula and then entering the mixer for uniform mixing. The mixing section requires a short mixing cycle, high mixing quality, fast discharge, low residual rate, good air tightness, and no dust spillage.

6. Pelleting process

The pelleted feed obtained by compacting and extruding a single raw material or compound mixture by mechanical action is called feed pelleting. The purpose of pelleting is to use the heat, moisture, and pressure in the pelleting process to pelletize the feed that is finely crushed, easy to dust, has poor palatability, and is difficult to transport.

7. Cooling process

In the pelleting process, when the pellet feed comes out of the feed pellet machine, the water content reaches 16%-18%, and the temperature is as high as 75°C-85°C. It can also cause sticking and mildew during storage. Moisture must be reduced to below 14%, the temperature must be below 8°C above air temperature, and cooling is required.

8. Crumbling process

In the production process of the feed pellet machine, to save electricity, increase productivity and improve quality, the material is often made into pellets of a certain size and then crushed into qualified products according to the size of the feed pellets.

9. Screening process

After the pellet feed is processed by the crushing process, some unqualified materials, such as powder, will be produced. Therefore, the crushed pellet feed needs to be sieved into a product with neat particles and uniform size.

10. Packaging process

After weighing, the finished product is put into the packing scale and packed. During this process, the package should be calibrated until the package weight standard is met.