Vertical FRP Tank Winding Machine

Specifications

Vertical Winding Machine for Large Scale FRP Tanks

Vertical FRP tank winding machine, as a high-tech electromechanical machine, is also designed for manufacturing winding molded tanks and vessels similar to horizontal FRP tank winding machines. However, this one fabricates vertical large-scale products from 4m to 25m in diameter on customer’s site. Equipped with thermosetting resin filament roving device, it winds filament helically around the rotating mandrel accurately to ensure stable and durable products.

/

Vertical FRP tank winding machine

Vertical FRP tank winding machine

Feature:

- Small covered areas for space-saving.

- Single structure allow for easy installation.

- Accurate control of mandrel rotation, trolley movement and winding process.

- Furnished with double filament roving feeders for both reciprocating cross and hoop winding.

- Good lamination design for quality products with excellent corrosion resistance, axial strength and anti-leakage property.

- Easy and convenient operation - just input the data to the PC control system.

- Low energy consumption, high productivity, low maintenance and lower production cost.

Composition:

- Track of winding machine.

- Rotating mandrels.

- Resin bath.

- Filament roving feeder.

- Roving guider.

- Optional resin mixing and transport device.

- Optional device including resin pre-accelerated agitator tanks, pneumatic filament chopped spray gun, resin pumps and catalyst flowmeters.

Application:

- Storage vessels for water and grain, etc.

- Municipal waste water treatment.

- Anti-corrosive tanks and large tower.

- Pollution control equipment.

- Fermentation tank.

- FRP desulphurization tank.

- FRP chimney.

- Chemical and petroleum areas.

- Medical industry and food processing.

Details:

- Control method: manual, semi-automatic and automatic.

- Transmission method: pinion and rack.

- Winding roving capacity: 80 each.

- Winding type: reciprocating cross, hoop direction.

- Resin type: unsaturated polyester, vinyl ester, etc.

- Yarn frame: mechanical yarn frame that a tension adjustable yarn frame of mechanical type.

- Impregnation groove: stainless steel groove for roller impregnation or immersion impregnation.

- Standards: complying with ASTM D3299-88, ASTM D-3300, HG T20696-1999 or other custom standards.

Specification:

| Parameters | FW-1000 | FW-1500 |

| Pipe diameter | 4000mm to 10000mm | 4000mm to 25000mm |

| Pipe height | ≤ 8000mm | ≤ 9000mm |

| Winding angle range | 70° to 90° | 70° to 90° |

| Maximum weight of pipe | 32000kg | 45000kg |

| Rotating speed of principle axis | ≤ 18r/min | ≤ 12r/min |

| Maximum speed of pulling yarn | ≤ 90m/min | ≤ 90m/min |

| Width of yarn | 50mm to 300mm | 50mm to 300mm |

| Production capacity | 2000kg/h | 2000kg/h |

| Total installed capacity | 15kW | 18kW |

| Size (L × W × H) | 10m × 12m × 10m | 15m × 18m × 11m |

/

A filament winded vertical FRP tank waiting for extraction.

A filament winded vertical FRP tank waiting for extraction.

/

Vertical FRP tank is demoulded easily using hoist machines.

Vertical FRP tank is demoulded easily using hoist machines.

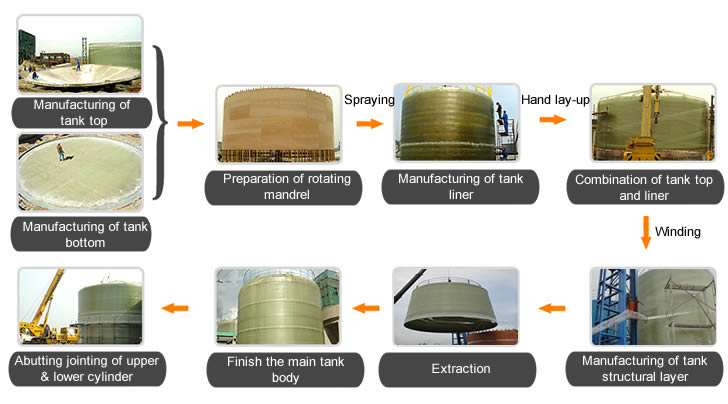

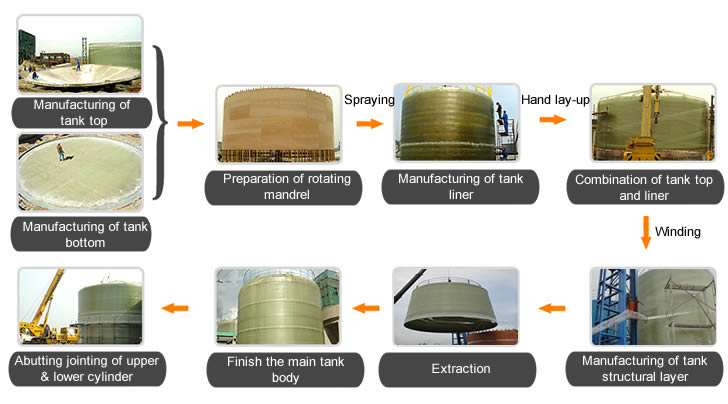

Vertical FRP tanks manufacture process:

/