Polished Rod Used With Sucker Rod and Hollow Sucker Rod

Specifications

Polished Rod Used in the Corrosion Environments

Introduction

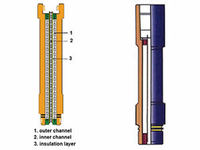

Polished rod is mainly divided into regular polished rod and end upsetting polished rod.

The polished rod is manufactured from high quality alloy steel, which is high tensile strength, smooth surface and long service life. All of the polished rod is produced in accordance with API Spec 11B. The polished rod is mainly has two types: regular grade D polished rod and end upsetting polished rod. The regular grade D polished rods are connected by the polished rod coupling, and the end upsetting polished rods are connected to the sucker rod directly for usage.

There is another type of polished rod, which has ultra-high tensile strength, long stoke and corrosion resistant polished rod. This type of sucker rod is made of 20CrMo alloy steel. It is heat treated by quenching and tempering and the rod surface is metal sprayed with nickel-based alloy (Ni35) to make the rod be better resistance to the corrosion and wear.

Specification

- Material: 20CrMo, stainless steel rod.

- Type: regular polished rod, end upsetting polished rod.

- Rod diameter: 1", 1-1/8", 1-1/4", 1-1/2".

- Length: 25', 26' and 30'. Other specs can be customized.

| Regular Polished Rod Specification | |||

|---|---|---|---|

| Item | EPRR-01 | EPRR-02 | EPRR-03 |

| Size | 1-1/8" | 1-1/4" | 1-1/2" |

| Rod body diameter | 1-1/8" | 1-1/4" | 1-1/2" |

| Thread nominal diameter | 15/16" | 1-1/16" | 1-3/16" |

| With of sucker rod size | 5/8" | 3/4" | 7/8" |

| Vanish cone | 9° | 9° | 9° |

| Standard length | 25', 26' and 30' | ||

| End Upsetting Polished Rod Specification | |||

|---|---|---|---|

| Item | EPRU-01 | EPRU-02 | EPRU-03 |

| Rod body diameter | 1" | 1-1/8" | 1-1/4" |

| Upsetting end thread nominal diameter | 1-3/16" | 1-3/8" | 1-9/16" |

| Non-upsetting end thread nominal diameter | 15/16" | 1-1/16" | 1-3/16" |

| With of sucker rod | 1-3/16" | 1-3/8" | 1-9/16" |

| Standard length | 25', 26' and 30'. | ||

Regular polished rod

End upsetting polished rod.

Package & container

- Package. The polished rod has strict package. It has 7 layers of package in total:

- Polished - anti-rust oil - plastic film - aluminum film bag - adhesive tape - single wall corrugated - packed into bundle.

- Container. The loading container of the polished rod is mainly 40' OT (40' open top container) and 40' GP (40' general purpose container).

Painting anti-rust oil.

Plastic film package of the polished rod.

Wooden box package of the polished rod.

Polished rod in open top container.

Features

- High tensile strength.

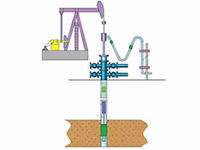

- Can be used with sucker rod and hollow sucker rod.

- Corrosion resistant.

- Solid and hollow structure for different requirements.

Application

- Polished rod is mainly used for connecting between the pumping unit and rod string in the oil well.

- The regular grade D polished rod is not used for high corrosion environments.

- The end upsetting polished rod can be used combined with sucker rod for usage.

- The corrosion resistant polished rod is used for pumping crude oil in deep wells, large displacement wells, thickened oil well and high corrosion wells.