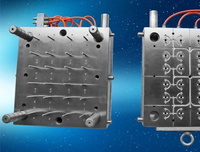

Preform Mold(24cavity PET Preform Mold)

Description

| Delivery Time: | 40-45days after deposit |

| Package: | Export criteria,with wooden box |

| Supply Ability: | 30 Set/Sets per Month |

| Minimum Order Quantity: | 1 Set/Sets |

| Payment Terms: | L/C,T/T |

| Port: | NINGBO or SHANGHAI |

| Fob Price: | US$1-1500NINGBO or SHANGHAI |

| structure: | pneumatic shut-off preform mold |

| Product: | preform mold |

| Product Material: | Plastic |

| Shaping Mode: | Preform Mould |

| Model Number: | Pneumatic Pin Valve preform mold |

| Brand Name: | Dongpeng |

| Place of Origin: | Zhejiang China (Mainland) |

Product Details

Jason

If any further requests on preform mold,pls feel free to contact me.

3), Precise Distributary Plate distributes cooling water into cavity evenly,quicken preform cooling.

2), Cooling System on neck and move neck plates enhance cooling performance.

1), Sprial Water Cooling Way on cavity enhances cooling performance.

4,COOLING SYSTEM

4), Hot Runner Balance design ensures evenly force,uniform heating and identical preforms.

3), Cavity-to-cavity control system ensure nozzle temperature fluctuates within 1oC

2), Use imported heaters,like Germany HOTSET and Italy ROTFIL

1), Less energy cost and pressure lost

3,HOT RUNNER SYSTEM

5), Double self-lock structure ensures mold thickness tolerance less than 0.1mm

4), Pneumatic Pin Valve strcuture without manual cut tail,reduce the labor force.

3), High quality materials and proven preform mold design ensure long life time

2), Excellent hot runner system and cooling system.

1), Core,Cavity and Neck can be interchanged.

2,MOULD FEATURES

2), Devote to professional packaging solutions for beverage,daily chemail, medicine

1), More than 10 years experience in Preform Mold

1,SERVICE

Preform mold with high quality materials

Proven preform mold design

Advanced hot runner system

Excellent cooling system

- structure:pneumatic shut-off preform mold

- Product:preform mold

- Product Material:Plastic

- Shaping Mode:Preform Mould

- Model Number:Pneumatic Pin Valve preform mold

- Brand Name:Dongpeng

- Place of Origin:Zhejiang China (Mainland)

You may also like

Relate products of Preform Mold(24cavity PET Preform Mold)

The Three Part Syringe Plunger from PLUSLINK is a durable and easy-to-use device designed to help inject medication into the body accurately and safely. It is constructed from three separate parts made from medical-grade plastic, allowing for easy maintenance, cleaning and ...

It is designed for various types of three-part syringe barrel.including luer slip, luer lock and dual-structural syringe. (1ml, 2ml, 2.5ml, 3ml, 5ml, 10ml, 20ml, 25ml, 30ml, 50ml, 50ml Catheter Tip, 60ml Catheter Tip, 100ml, 150ml) It consists of three main components: the ...

LINKPLUS provide precision molds used in manufacturing of each components of the various syringes such as disposable syringe, Insullin syringe, safety syringe, AD syringe. Including barrel, plunger, gasket. It\'s customizable according to customer production need. Our syringe ...

It can be used for all kinds of dimension of pistons. There are materials of 4Cr13 or P20H, 2738, 718 stainless steel and etc. It can be selected for mold frame, material customer nominated is acceptable. It is the high precision of mold inner insert is S136, 2316 mirror ...

We are an unparalleled name in offering a wide gamut of precision wire cutting parts. These wire cutting parts are amongst the most desirable and reliable products in the industry. The offered spare parts are manufactured using the best grade raw material under the supervision ...

A mould trial is a process by which a new mould is optimised in order to produce the desired products as efficiently as possible. This makes it one of the most important aspects of injection moulding. DETAIL OF TRIAL MOLDING Trial Molding Process Set barrel temperature ...

A thread is a continuous helical ridge formed on the inside (nut) or outside (screw) of a cylinder. This ridge is called the crest. Between each crest is a space, called the root. Threads are set at an angle to the axis of the bolt or nut. We provide quality threaded parts. ...

We provide DIN(Deutsche Industrie Normen) standard mould parts of high quality to our customers. The mold standard parts are applied to all kinds of mold base and mold holders. As a professional precision mold supplier, we will provide good services to satisfy different ...

Stamping — also called pressing — involves placing flat sheet metal, in either coil or blank form, into a stamping press. In the press of stamping components making, a tool and die surface form the metal into the desired shape. Punching, blanking, bending, coining, ...

When it comes to custom injection molding, precise moulds and precision equipment are required for precision molding or PIM. Among the topics covered in this blog are general ideas, specific traits and qualities, as well as specific options for plastic materials, precision ...

See larger image: Preform Mold(24cavity PET Preform Mold)

See larger image: Preform Mold(24cavity PET Preform Mold)