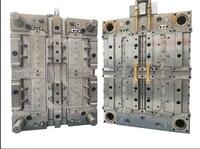

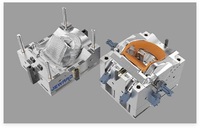

IMD parts / plastic injection mould

Description

| Delivery Time: | 7 days |

| Package: | according to our customer's requirement |

| Supply Ability: | 2000 Piece/Pieces per Day |

| Minimum Order Quantity: | 1000 Piece/Pieces |

| Payment Terms: | T/T |

| Port: | ShenZhen |

| Fob Price: | US$2-5ShenZhen |

| Tooling lead time: | 15 days |

| Technique: | In Mold Decoration |

| Color: | Vacuum metalization plating+silk screen printing |

| Surface effect: | 3D printing is available |

| Construction: | 3D shape |

| Material: | Hard coating PET+Resin |

| Brand Name: | OEM |

| Place of Origin: | Guangdong, China (Mainland) |

Product Details

You are warmly welcome to contact with us for our any products and visit our factory at any time.

Should any of these items be of interest to you, Please let us know and provide products of the 3D images file.

-Other industry:Cosmetic box, Gift box, decoration box, toy, Plastics products etc

-Computer industry: Keyboard ,Mouse cover etc

-Atuomobile industry: Instrument panel, Air conditioning panel, Inside decoration, Light cover,

-Electron industry: MP3, MP4, laptop, DVD, Electric notepad, Camera etc

-Household appliances industry: Electric cooker,Washing machine, Micro-wave oven,Air conditioner,Refrigerator, induction oven, bread maker etc.

IMD is popular use for below fields.

4. Long-lasting Graphics

3. Multiple Colors, Effects, & Textures with a Single Operation 3D graphics is available

2. Design Flexibility

1. Cost Effective (requires 1 part = lower tooling, adhesive and assembly costs)

The main benefits of IMD is following.

IMD is a molding process where a label with graphics is placed in the mold prior to injection to become a more permanently attached to the part.

In Mould Decoration (IMD) is one of the most efficient and cost-effective ways of decorating a part is to do it during the molding cycle.

Below is the brief presentation of IMD for you reference.

Shenzhen Simton Technology Co.,Ltd produce the IMD parts for variants of household appliances, consumer electronic, automotive etc. We are the real factory, not trading company. All of the processes of IMD are in house, including silk-screen printing, vacuum plating, tooling, forming, stamping and injection.

- Welcome OEM products

- Tested one by one before sending to customer

- Excellent material to make sure durable performance

- With logo or without logo are available

- We can develop any kinds of molds according to customers' design

- ISO 9001:2000 Certificated

-This is a new technology (In Mold Decoration) which is be used in the plastic parts

IMD parts / plastic injection mould

IMD parts is our strong item to export,high quality OEM kind and various models kind both available

- Tooling lead time:15 days

- Technique:In Mold Decoration

- Color: Vacuum metalization plating+silk screen ...

- Surface effect:3D printing is available

- Construction:3D shape

- Material:Hard coating PET+Resin

- Brand Name:OEM

- Place of Origin:Guangdong, China (Mainland)

You may also like

Relate products of IMD parts / plastic injection mould

At present, more than 90% of plastic products in our daily life are injection molded. The market prospect, capacity, and application are large and wide. The following are the basic review of plastic injection moulds\' classifications. Hanking Plastic Injection Moulds includes ...

Plastic Injection Moulding Die Makers Plastic mould die maker in China Focus on all kinds of mould development, various plastic mold manufacturing, mould design, injection molding, silk screen, tampon printing, assembly, about 300 sets plastic injection moulds are exported each ...

At present, more than 90% of plastic products in our daily life are injection molded. The market prospect, capacity, and application are large and wide. The following are the basic review of plastic injection moulds\' classifications. Hanking Plastic Injection Moulding includes ...

Plastic injection moulding die makers & plastic mould die maker in China Focus on all kinds of mould development, various plastic mold manufacturing, mould design, injection molding, silk screen, tampon printing, assembly, about 300 sets plastic injection moulds are exported ...

The practicality of plastic basket injection mould is very high. Such as a plastic fruit drain basket, it is small and light, with a hollow design, which is convenient for cleaning fruit, and has a large capacity for draining water to ensure the cleanliness of the fruit. At the ...

Our round plastic paint bucket injection mould has different capacities, such as 1L, 4L, 12L, 15L, 17L, 18L, 19L, 20L, etc., the size can be customized according to customer requirements. plastic paint bucket application: It is mostly used for the storage and transportation of ...

Among the three key elements of injection molding industry, material, machine and mould, the plastic injection mould is the most important and changeable one. It brings countless changes to plastic products. And because of the variety of products, processes and materials, the ...

CNC Machining or Not: Cnc Machining Type: Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Wire EDM Material Capabilities: Aluminum, Brass, Bronze, Stainless steel, Steel Alloys, carbon fiber,plastic,glass,rubber,wood etc. ...

PA66 GF30 Car Parts Plastic Injection Mold If you want to get the product is straight, your mold design and mold processing are also made straight, but there will be a bent product, deformed or the product size is out tolerance, they were caused by material, temperature, ...

Name:Plastic Pet Hair Brush Comb Injection Mould Brand Name: Anye Place of Origin: Taizhou, Zhejiang, China Plastic material: PS, ABS, PP, PVC, PMMA, PBT, PC, POM, PA66, PA6, PBT+GF, PC/ABS, PEEK, HDPE, TPU, PET, PPO Cavity/Core Steel: P20, 2311, H13, 2344, Starvation 420, 236, ...

See larger image: IMD parts / plastic injection mould

See larger image: IMD parts / plastic injection mould