Rubber mold (mould)

Description

| Delivery Time: | 30days or as per customers' requirement |

| Package: | Wooden packing or as per customers' requests |

| Supply Ability: | 30 Set/Sets per Month |

| Minimum Order Quantity: | 1 Set/Sets |

| Payment Terms: | L/C,T/T |

| Port: | XIAMEN |

| Product: | industrial products |

| Product Material: | Metal |

| Shaping Mode: | Extrusion Mould |

| Place of Origin: | Fujian China (Mainland) |

Product Details

We are specialized in designing and manufacturing precision rubber injection mold and products more than 10 years. And has enjoyed a good reputation with all of our clients at home and abroad for our competitive quality & price & best after-sales serves. We are the supplier you can trust in China!

8) Fast quotation

7) OEM order are welcomed, ONE set are also available. We are also supply precision tooling and molded precise parts, prompt delivery.

6) We use the advanced mold design software such as Auto-CAD and UG. We owned advanced equipment, such as CNC, EDM, wire-cutting, milling machine, grinding machine and so on.

5) Cavity number: single, multi cavity

4) Standard: ISO9001: 2000 certificated by SGS

3) Perfect appearance of molded parts

2) Product material: YG15/KG7, MISUMI, PUNCH, SKH-9/KD20/V30/V40/SKD-11etc

1) Rubber mould with more than 1,000,000 shots life

We can supply any kinds of rubber mould and products subject to customers' requirement. Especially on the price , quality& serve

- Product:industrial products

- Product Material:Metal

- Shaping Mode:Extrusion Mould

- Place of Origin:Fujian China (Mainland)

You may also like

Relate products of Rubber mold (mould)

LINKPLUS provide precision molds used in manufacturing of each components of the various syringes such as disposable syringe, Insullin syringe, safety syringe, AD syringe. Including barrel, plunger, gasket. It\'s customizable according to customer production need. Our syringe ...

Silicone rubber is a kind of elastic material, which is widely used in industry and family. It has become an important part of our life. Meanwhile, silicone moldings are becoming more and more important in the world because it is widely used in a variety of industries like ...

Packson\'s state-of-the-art facilities consist of a 1000㎡ certified clean room, which is equipped with 14 sets of Liquid Silicone Rubber (LSR) injection machines. This enables Packson to produce up to 50 million medical-grade LSR components per year, ensuring that clients\' ...

TheTDP Tablet Press Die Molds are precious with special alloy steel, drawing is designed by computer, manufactured by high and precise numerical control machine. The special feature of TDP molds is high hardness, high malleability, and high abrasion.TDP die molds are not only ...

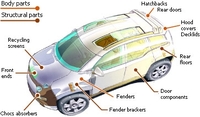

SMC Automotive Molding, Car Mould Cars, buses, trucks, transport and special vehicles • Weight: Parts made from sheet molding compound (SMC) are typically 25-35% lighter than steel parts and aluminum products of the same strength. The stroke is increased and the fuel ...

In the past 10 years, over-moulding technology has completely changed the aesthetic standards, design ideas and functional requirements of consumer goods. Medical device manufacturers also recognize the potential advantages of the technology and continue to expand its ...

In order to meet the needs of installation and connection, or to increase the strength of the plastic part, suitable metal parts are designed to insert into plastic molding parts, making an integrated products of both metal and plastic. The connector is designed with brass ...

In the past 10 years, over-moulding technology has completely changed the aesthetic standards, design ideas and functional requirements of consumer goods. Medical device manufacturers also recognize the potential advantages of the technology and continue to expand its ...

GA-90*1A/B series platinum catalyzed silicone mold making operates easily, A:B: mix evenly according to 1:1 ratio, product transparency is good, suitable for platinum vulcanization. The production of medical and health products needs to be treated by secondary vulcanization at ...

In order to meet the needs of installation and connection, or to increase the strength of the plastic part, suitable metal parts are designed to insert into plastic molding parts, making an integrated products of both metal and plastic. The connector is designed with brass ...

See larger image: Rubber mold (mould)

See larger image: Rubber mold (mould)