Single Screw Plastic Extruders

Description

|

Features : High output, low power consumption, less friction, lower shearing rate and forced extruding. |

Product Details

Features :

|

Major Benefits :

|

|

Applications : Our extruder are used to manufacture RPVC Pipe, PVC Profile, HDPE Pipe, PPR Pipe, PVC Cable, XLPE Cable, Re Processing, LLDPE Tubing, PVC Compounding, HM Film, LD Film & PVC Film |

Features :

High output, low power consumption, less friction, lower shearing rate and forced extruding.

You may also like

Relate products of Single Screw Plastic Extruders

What is a Twin-screw Feed Extruder? The H series twin-screw feed extruder is primarily used for the production and processing of various floating, sinking, and slow-sinking aquatic feeds. It can meet various customer demands, including 0.6mm aperture floating and 0.8mm aperture ...

直径范围:Ø15mm~Ø500mm 长径比:L /D=7~55 材质:38CrMoAIA(41CrAIMo7) 调质硬度: HB280-320 螺杆直线度: 0.015mm 氮化硬度: HV850-1000 氮化深度: 0.45~0.7mm 氮化脆性:2级 表面粗糙度:≤Ra0.4 ...

PVC is a non-crystalline polymer of polyvinyl chloride. Its glass transition temperature is 105℃-75℃ depending on the molecular weight. It has flame retardancy, high rigidity, excellent chemical resistance, and electrical insulation, but it is a heat-sensitive resin. Its ...

The fully automatic one-step plastic film extrusion equipment is our company\'s patented product. Fully automatic film extrusion equipment: mainly used for processing various mixed plastic film materials to produce products, mixed waste plastic films: household garbage film, ...

Plastic uniaxial shredder is mainly used for shredding hard plastics, such as: machine head material, trays, shredding of daily miscellaneous hard waste plastics, household appliances, etc. As a professional single-shaft plastic shredder machine manufacturer, we provide ...

Single Screw Plastic Waste Granulator The single screw waste plastic granulator is mainly suitable for extrusion and granulation of raw materials, which is not only clean or single with stable components and low moisture content, but also has no need for secondary ...

The extruder open screw barrels are used in the feeding section, the natural exhausting section and the vacuum exhausting sections. Depending on the materials produced, the placement of the open barrel is different. The opening shapes of twin barrel screw can be square, ...

Model 800 Power (kw) 30 Pushing power (kw) 2.2 Single shaft wood shredder’s information ...

ScrewBarrel forExtruder There are two maintypes of screw barrel, 4D and 6D, with 4D being the most. According to the different selection of the materials from the customers, the corresponding bushing materials can be selected to meet the needs of the modified customer. ...

WITH REGARD TO PRODUCTION SPECIFICATIONS, LESUN NOT ONLY OFFERS STANDARD TWIN SCREW EXTRUDER PARTS MADE BY GENERAL SCREW EXTRUDER MANUFACTURER, BUT ALSO PROVIDES SPECIAL-PURPOSE FEED SCREW DESIGN AND MANUFACTURING SERVICE ACCORDING TO YOUR REQUIREMENTS. MEANWHILE, WE ALSO ...

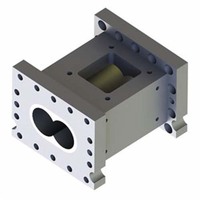

See larger image: Single Screw Plastic Extruders

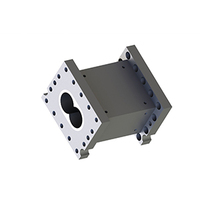

See larger image: Single Screw Plastic Extruders