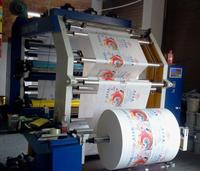

GALLANTIC1217 CD HIGH SPEED OFFSET PRINTING MACHINE

Description

| The GALLANTIC1217 CD HIGH SPEED OFFSET PRINTING MACHINE employs the process of offset lithography to make reproduction of a desi |

Product Details

The GALLANTIC1217 CD HIGH SPEED OFFSET PRINTING MACHINE employs the process of offset lithography to make reproduction of a desi

You may also like

Relate products of GALLANTIC1217 CD HIGH SPEED OFFSET PRINTING MACHINE

QH high speed corrugated carton lead edge feeder flexo Printing Die Cutting Machine 序号 参数名称 name 单位 规格 1 机械内侧宽度 Machine insdie width mm 2600 2 设 计 速 度 Design speed 张/分 Pcs/min 150 3 经济运行速度 Economical speed 张/分 Pcs/min ...

Major configuration 1.Low speed and full load startup; stable running by tension control when increasing and decreasing speed , noise is decreased 2.High dots presentation rate under high speed; clear and vivid stratification of screen printing; strong stereo effect and ...

Model Number:byc168 Brand Name:boyichuang Place of Origin:Yunnan China (Mainland) Disk Duplication:No Printing Type:Digital Printing Product Type:Disk Digital all-purpose flatbed printer(A4-A1) can print on any kind of material (e.g. wood, textile,glass and so on ). ...

Kunming Boyichuang Science & Technology Development Co., Ltd.

Printing Slotting & Die-cutting Machine We supply entire carton production line,and various single packing machine be provided ...

Printing Type:Digital Printing Product Material:Plastic Color & Page:Multicolor Usage:Label Printer Plate:Flatbed Printer Type:Inkjet Printer Model Number:byc168 Brand Name:boyichuang Place of Origin:Yunnan, China (Mainland) Place of Origin:Guangdong China (Mainland) Product ...

Kunming Boyichuang Science & Technology Development Co., Ltd.

Wilsoneme:Wilson Company Color & Page:Multicolor Usage:Paper and Plastic Film Printer Plate:1.7mm or 2.28mm resin image plate Type:Flexographic Printer Model Number:WS808-600GSi Brand Name:Wilson WS8GSi Series Place of Origin:Hong Kong 8c High Speed Flexographic Printing ...

SYKM950-2200 HIGH SPEED FLEXO PRINTING & SLOTTING & DIE-CUTTING MACHINE ...

Color & Page:1-20 Usage:film printer Plate:Gravure Type:Rotogravure Printing Machine Model Number:KELI PT1800 Brand Name:KELI Place of Origin:China (Mainland) KLFX-Computer-Controlled Intaglio Printing Machine In High Speed ...

Color & Page:Multicolor Usage:Other Plate:Gravure Type:Rotogravure Printing Machine Place of Origin:China (Mainland) Rotogravure printing mache are applicable for continuous multi-color printing on rolling materials ...

Material::Film and paper Printing colors:1-10 colors Printing speed:120m/min Unwinder and rewinder:non stop Computer:two computers Color & Page:Multicolor Usage:plastic,paper Plate:Gravure Type:Rotogravure Printing Machine Model Number:BSY-B Brand Name:XH Place of ...

See larger image: GALLANTIC1217 CD HIGH SPEED OFFSET PRINTING MACHINE

See larger image: GALLANTIC1217 CD HIGH SPEED OFFSET PRINTING MACHINE