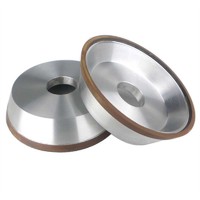

cnc grinding wheel Diamond and CBN grinding wheels

Quick Detail

- FOB Price : USD $50.00 / Piece

- Minimum order:1

- Place of Origin:China

Specifications

JR diamond tools is an experienced manufacturer of High Quality Diamond and CBN grinding wheels. JR diamond tools company supplies the wheels for several applications:

Carbide Round tools on CNC machines: Flute Grinding, Gash Grinding, end facing, Clearance angle Cylindrical grinding.

Insert grinding for machines such as: AGATHON, WENDT, HAAS, WAIDA and EWAG.

Woodworking saws and tools.

HSS tools.

Cut off wheels.

/

STORAGE

Diamond and CBN grinding wheels should be carefully stored in original packaging and the core should be kept oiled.

MACHINES

Machines should be in good working condition, well maintained and free of vibration. Special attention should be given to the spindle which should run true and the spindle bearings which should be in good condition.

WHEEL MOUNTING

After cleaning and checking the mounting arbor and flange, the wheel should be running true to within 0.02 mm.

COOLANT

• Synthetic oil – Most popular

• Emulsion (water based)

Water with an added rust inhibitor is sufficient for diamond grinding wheels. The life of CBN grinding tools can be significantly extended by using pure oil yet an emulsion with oil concentration should be sufficient.

CUTTING FLUIDS

Cutting fluids should be used whenever possible when using diamond wheels, to reduce the heat generated by grinding as well as to extend the wheel’s life. If it’s necessary to dry grind, a corret resin-bond wheel should be used.

COOLANT FLOW

The best cooling effect is achieved when the outlet speed of the cooling lubricant is adapted to the peripheral speed of the grinding wheel, and the nozzle opening is only slightly wider than the grinding rim.

A small trickle of coolant occasionally applied, is better than no coolant at all. This causes alternate heating and quenching, which can cause damage to the diamond wheel and carbide tools.

/

/

FLUTE GRINDING

Grinding wheels used: 1A1, 1V1, 14A1, 14V1, 3A1, 3V1

As flute grinding accounts for the majority of grinding time it is essential to optimise the machine, cooling systems and grinding wheels. POMDI has developed a new hybrid bonding agent that removes high volumes at material at high operating speeds whilst minimising grinding wheel wear. This bonding agent also lowers energy consumption.

RELIEF AND GASH GRINDING

Grinding wheels used: 12V9, 1V1, 14V1

This process also sometimes needs to remove a lot of material. Consequently, the objective is to maximise cutting capacity whilst minimising grinding wheel wear.

CLEARANCE ANGLE AND OUTER DIAMETER

Grinding wheels used: 11V9, 6A9, 6V5, 11A2, 12A2, 11V5, 12V5, 12V2

Clearance angles are used on the face and around the lip to reduce the contact surface between the tool and the workpiece during drilling or milling.